3D optical alternatives to approach Industry 4.0

Tekniker is involved in a European project whose aim is to design guidelines on best practices to implement new industrial measurement techniques.

One of the principal demands made by European Industry 4.0 is related to having quicker and more accurate measurement systems to meet the needs of a demanding market that is becoming increasingly competitive.

It is in this field that 3D optical measurement techniques and technologies (microscopes and sensors integrated in CMMs) now offer the possibility of analysing surface finishes of industrial components in an agile and contactless manner, a determining factor in terms of production effectiveness.

Not surprisingly, it has been estimated that 10% of the parts manufactured fail due to surface effects, a fact associated with economic implications.

Since 2021, and with a view of establishing traceable and standardised measurement methods for these optical systems and processes, Tekniker technology centre, a member of the Basque Research and Technology Alliance (BRTA), has been involved in the European TRACOPTIC project that has tested a number of tools such as 3D microscopes and different types of optical sensors to facilitate their implementation in industrial environments.

Gorka Kortaberria, the person in charge of the project, explains that “optical measurement systems save time and money in industrial processes, they improve the competitiveness of European companies and reduce outsourcing to other regions. They also provide early detection of faulty parts and reduce the amount of waste produced. The fact that there is no contact prevents surface deterioration from occurring and makes it possible to measure geometries that are very complex or small”.

The ultimate purpose of this initiative is to develop guidelines on best practices to be implemented by companies, manufacturers, laboratories, research institutions and universities dealing with optical measurement techniques always bearing in mind the different geometrical characteristics that can be found in a number of sectors such as the automotive business, aeronautics or bio-healthcare to select optimum instrumentation and procedures for each individual case.

Validation and simulations

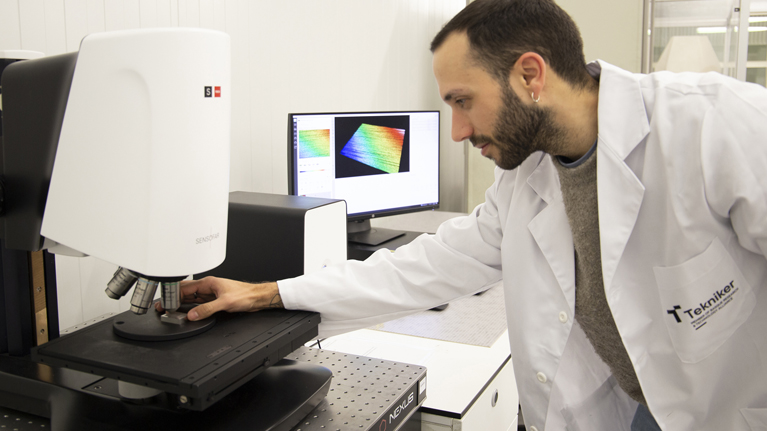

As a technology centre characterised by a high degree of specialisation in the area of industrial metrology, Tekniker’s remit is focused on validating the capacities and constraints of a 3D optical profilometer to measure different kinds of samples.

The device uses a high-resolution optical technique (white light interferometry) and has been equipped with a low-coherence light source to measure surface height and topography at a micro and nanometric scale.

Gorka Kortaberria explains that “the technique is based on measuring the amount of interference between the light reflected on the surface and the reference light to allow the topography of a surface to be built with a high degree of accuracy and resolution”.

Tekniker is also participating in the development of good use practices for the measurement techniques included in the project and is collaborating in the fine-tuning of digital twins to verify the scope of measurement systems via simulations.

“The technology centre’s expert also states that “thanks to digital twins, it is now possible to obtain a model of the microscope with its characteristics and simulate a large amount of real surface measurements to provide a statistical distribution of the results prior to executing the measure”.

As a result of this analysis, companies will be able to produce a “map” showing the capabilities of each instrument subject to evaluation and take scientifically-based decisions to select the most suitable optical measurement system that can meet their characterisation needs.

The TRACOPTIC project, co-funded by the European Partnership programme on Metrology and the EU’s Horizon 2020 programme consists of 24 stakeholders with organisations like Tekniker and other national metrology institutes from 9 European countries: PTB (Germany), CEM (Spain), DFM (Denmark), GUM (Poland), INRIM (Italy), LNE (France), RISE (Sweden), VSL (Netherlands) and VTT (Finland).

This project has received funding from the EMPIR programme co-financed by the Participating States and from the European Union’s Horizon 2020 research and innovation programme.