R&D to place Spain at the forefront of green hydrogen in Europe

The Tekniker technology centre is currently involved in the H-LEAF project to produce cutting-edge technologies to carry out an energy transition that is more autonomous, safer and environmentally friendly.

The aim of the European Green Deal is focused on achieving climate neutrality 2050 in the continent by gearing the EU’s economy towards a sustainable model based on renewables to replace fossil fuels.

Although the energy transition intends to boost green hydrogen as a key vector, many challenges will have to be addressed due to high costs and to a limited degree of technological maturity. It is therefore essential to invest in R&D to overcome these barriers and advance towards a sustainable and clean energy system.

In order to address this challenge, the Tekniker technology centre, a member of the Basque Research and Technology Alliance (BRTA), is currently collaborating with the H-LEAF project to research and develop advanced technologies that can produce green hydrogen efficiently, economically and sustainably. High-pressure compression is also needed to meet storage requirements.

Based on cutting-edge components and processes, the initiative will strengthen Spain’s capabilities with regard to developing an energy transition that is more autonomous, safer and environmentally friendly.

It is expected that R&D work related to the project will eventually give rise to a prototype of an innovative electrolyser using Proton Exchange Membrane (PEM) technology to make it easier to produce hydrogen and develop a new compressor that is more efficient, safer and is specifically designed for high-pressure operations in which hydrogen is involved.

Coatings for critical parts

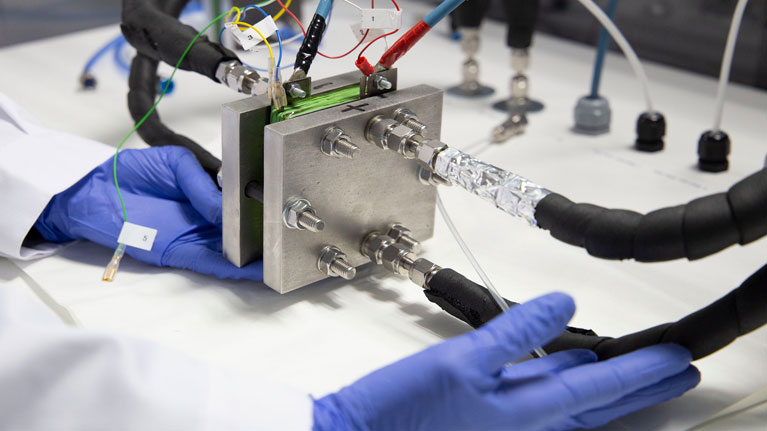

Throughout the initiative, Tekniker will research and develop advanced coatings for several critical electrolyser components such as bipolar plaques that are essential to separate water into oxygen and hydrogen molecules efficiently.

Eva Gutierrez, Head of the Plasma Coating Technology Unit at Tekniker explains that “we will develop PVD coatings by applying a thin layer of advanced materials on the electrolyser’s bipolar plaques. In order to do so, we will use 3D printing techniques with recycled titanium powder and stamped stainless steel to make parts that are more durable and efficient. We will also cut back on production costs”.

The technology centre, moreover, will develop specific coatings for the new compressor’s parts to increase durability, reduce system leaks and allow for high-pressure operations (400-500 bar), a prerequisite to store and transport the green hydrogen that is produced.

In parallel, Tekniker technicians will look into how these materials behave when in contact with hydrogen and under friction to evaluate their wear resistance, permeability to prevent leaks and embrittlement to ascertain their operating life.

The H-LEAF project, that will end in December 2026 and is funded by CDTI with the support of the Ministry of Science & Innovation via the TRANSMISIONES 2023 programme, intends to facilitate the transition towards clean and renewable energy and help strengthen the local technological industry.

In addition to the Tekniker technology centre, the consortium also features other leading industrial firms such as Rotatives Offset S.A.; Brendle Metalquímica S.A.; Industrias de Estampación del Corte Fino S.L.; Vilaseca Consultors S.L.P.; The Lean Hydrogen Company S.L.; Arizaga, Bastarrica y CIA; Jorcar 2009 S.L.; and Fundació Eurecat.

This publication forms part of the R&D&I project PLEC2023-010219 funded by MICIU/AEI/ 10.13039/501100011033 and, as pertinent, by: “FEDER a way to make Europe Europa”, “FEDER/UE” or for the “European Union NextGeneratioEU/PRTR”.