A unique robotic remote maintenance solution for the ESS neutron source

Tekniker is developing an specific “remote handling” solution that will allow maintenance operations be carried out in spaces that are difficult to access in the European Spallation Source (ESS).

Maintenance tasks are indispensable to guarantee the safety and proper operation of cutting-edge scientific facilities. Sometimes, however, these processes pose complications if spaces to be reached by technicians are either very small or practically inaccessible. In such instances, automation and technology can play the role of two strategic allies.

The Tekniker technology centre, member of the Basque Research and Technology Alliance (BRTA), an organisation with extensive expertise in projects of this nature, has been asked to design, manufacture, assemble and install a unique, customised robotic solution that can perform remote maintenance and supervise areas workers cannot reach at Europe’s new neutron source currently under construction in Lund (Sweden).

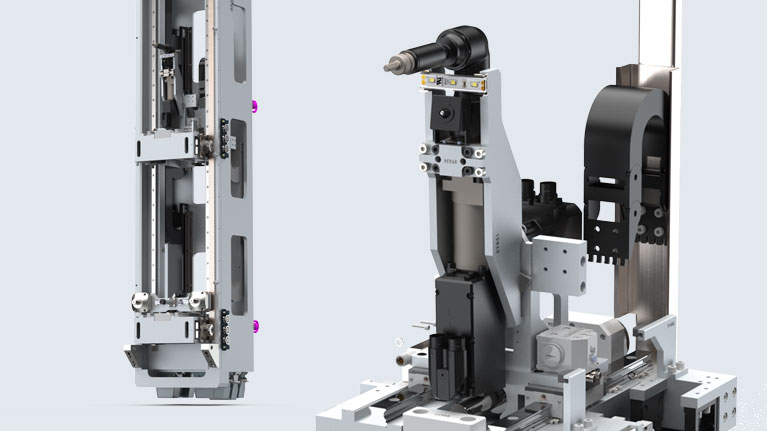

More specifically, Tekniker researchers are working on the so-called “Neutron Beam Window Hot Handling Tool” which is a fully automated remote handling solution that allows maintenance operations to be carried out in the path crossed by the neutron beam.

As explained by José María Seara, director of the Tekniker Unit for Design, manufacturing and Assembly ”there is a total of 42 neutron beam windows that can only offer limited access and the system developed for maintenance purposes has three subassemblies: two of them handle the windows whilst the other one screws and unscrews the joins between them”.

The technology centre has resorted to its multidisciplinary capabilities with regard to mechatronics, metrology, software, artificial vision and robotics to develop this mechanism that is backed by the knowledge and expertise acquired in other similar cutting-edge projects in the area of science industry.

The Tekniker researcher also stresses that “we have been able to meet a need for which market solutions could not be used. The solution is fully customised and has been adapted to the neutron source environment to interact and communicate with all the other elements and safety mechanisms”.

A key role in an international project

Tekniker’s development proves the significance of the role the organisation is playing as a technological supplier to the European Spallation Source (ESS) within the framework of a collaborative project with the ultimate goal of building the world’s most powerful accelerator-based neutron source to boost research in areas such as energy, health and the environment based on its capacity in terms of analysing the structures and properties of matter.

In addition to the technological solution applied to window maintenance that will finish in March 2024, the technology centre is also developing an ultra-high vacuum clamping mechanism to be installed in those places where manual interventions are impossible due to environmental constraints. The mechanism, called “Remote Clamp”, has already been installed on the scientific equipment.

It has been estimated that the construction of ESS will be completed in 2027, with the facility entering steady state operations in 2028.