Advanced biomaterials to regenerate the peripheral nervous system

IK4-TEKNIKER has developed implants based on biocompatible materials to make further progress in the field of peripheral nerve regeneration

The complexity of the peripheral nervous system and its regeneration mechanisms represent major enigmas for science. The focus, however, on development and research actions applied to regenerative medicine has brought about significant progress with regard to designing cutting-edge biomaterials and manufacturing technologies that can recover the functionality of nerves and neurons in a post-injury situation.

It is within this context that the European project NEURIMP has taken place. It is an initiative lead by the Basque technology centre IK4-TEKNIKER, that has made it possible to develop biocompatible and biodegradable implants to regenerate peripheral nerves. The results of this research carried out on rats have been successfully validated on a sciatic nerve model developed by the National Quadriplegics Hospital in Toledo.

“One of the main achievements of this project has consisted in manufacturing biomaterials for implants that mimic the mechanical properties of the injured nerve where grafting is performed. In this manner, their regeneration is facilitated whilst the tube of the implant is fixed by suturing it to both ends of the damaged nerve. Functional recovery, moreover, takes place before implant biodegradation occurs in the body and protects the regeneration of the damaged nerve", says Santos Merino, the head of the project at the technology centre.

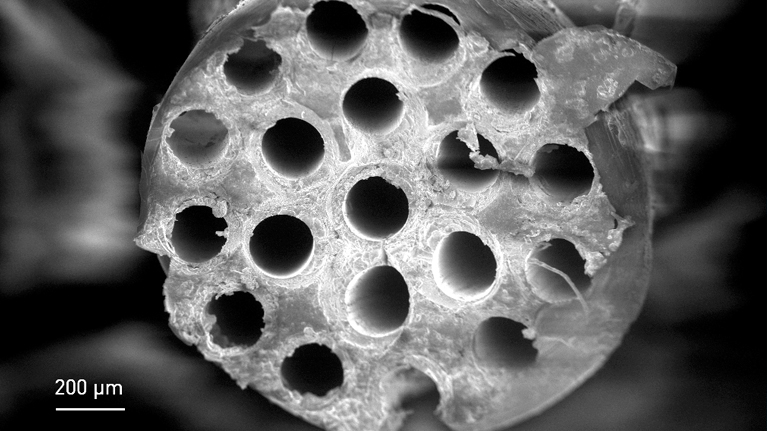

Specifically, the implants that have been developed are characterised by a hollow tube geometry with an internal component in the form of micro channels or fibres that allow neuronal cells to proliferate from the end of the damaged nerves to the opposite side.

Merino also adds that “this geometric layout does not only allow for cell proliferation in the nerve fascicle itself, but also prevents uncontrolled growth of axons, axes or neuron extensions whose main task is to carry nerve pulses from one cell to another.

The role played by IK4-TEKNIKER

In addition to coordinating the project, the technology centre has focused its activities on developing technologies under specialised areas of surface engineering and advanced manufacturing at the centre such as, for instance polymer processing at a micrometric scale, including clean room procedures, to optimise the implant´s tubular structure (formed by a hollow tube and an inner part comprising micro channels).

The Basque technology centre has also worked with synthetic polymers and natural polymers synthesised by other partners in the consortium, and with blends too. It has also adapted micro manufacturing technologies to the biophysical properties of new materials.

In addition to IK4-TEKNIKER, another two organisations have been involved in the project, namely, the National Quadriplegics Hospital in Toledo and Histocell, a Basque biopharmaceutical firm specialised in regenerative medicine.

The British universities of Sheffield and Westminster, Qserve, a Dutch consultancy firm and Vornia Biomaterials (Ireland) and Contipro (Czech Republic) have also participated in this initiative.

The European Commission is of the opinion that the NEURIMP project that began in January 2014 and closed at the end of 2017 has been a complete success.

Towards a new implant paradigm for patients

Generally speaking, lesions involving the peripheral nervous system in patients are usually caused by traumatic accidents and may produce loss of motor control as well as alterations in sensorial function. Consequently, lesions of this kind are linked to a severe incidence in terms of quality of life for thousands of people.

“The results of the NEURIMP will serve to lay the foundations required to develop prostheses manufactured with new materials that are capable of replacing autologous implants used nowadays on humans with lesions involving their peripheral nervous system”, says Merino.

A segment taken from the patient´s sural nerve is extracted and implanted in the damaged nerve. There are certain constraints, however, such as the need to perform a second surgery, the loss of nerve function during transplantation or a lack of correspondence between the cross section of the donor and the receptor nerve.

Two new patents

The project has given rise to two new patent applications. One of them has been filed in the United Kingdom and its aim is to safeguard the use of a number of natural polymers as a solution to regenerate peripheral nerves.

The second patent has been processed through the Patent Cooperation Treaty (PCT) requesting simultaneous protection in a large number of countries and coverage for the combination of biomaterials, their properties, implant production and in-vivo validation.

The signatory organizations of this second patent application, among them IK4-TEKNIKER, have initiated contacts with manufacturers of commercial tubing based on sharing development actions and studying different collaboration options.