Advanced surfaces to extend life cycles of offshore wind power facilities

Within the framework of the AVANSURF project Tekniker has collaborated to develop new multifunctional coatings for the offshore wind power sector and provide new monitoring technologies to assess the degree of corrosion affecting coatings in order to overcome a number of technical challenges associated with marine environmental conditions.

As they are more efficient, offshore renewables offer and outstanding alternative that has been taken on board by several European programmes whose aim is to foster the implementation of green energy research actions. Offshore materials used to produce energy, however, must withstand very harsh conditions such as ultraviolet radiation, chlorine-laden saline environments, constant drying and wetting cycles, and damages produced by biological microorganisms, marine bacteria and relative humidity.

Other problematic issues are related impacts, abrasions and severe wear produced by sand, waves, marine currents or floating debris.

Tekniker, an organisation with a vast amount of expertise in the energy sector, has provided the organisation’s knowledge in terms of surface engineering and ICT to allow the AVANSURF project to overcome technical challenges associated with offshore environmental conditions that wind power components must withstand. It will also deliver innovative sensor systems for early-stage fault detection.

The aim of the solutions developed during under this initiative is to extend the life cycle of offshore facilities by improving the quality of the steel used to manufacture structural components, developing new formulations for multifunctional paint to obtain high performance coatings and installing real-time monitoring systems to constantly control and predict levels of degradation affecting elements exposed to the marine environment.

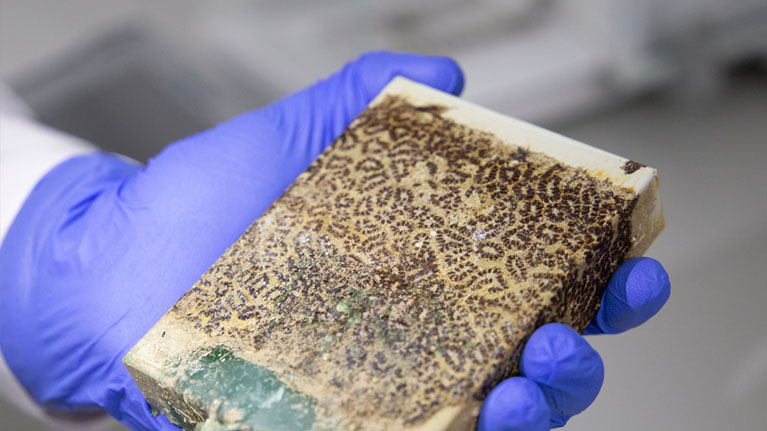

Several coating and sensor-based solutions have been validated within the framework of this project under real conditions at the Marine Corrosion Test Site “El Bocal”, an open sea Marine Laboratory located off the coast of Cantabria near Santander and the port of Mutriku (Gipuzkoa).

Electrode sensor for monitoring

Consequently, the AVANSURF project has brought about a large number of technological innovations as regards developing materials and surface treatments for offshore wind power facilities. Another major innovation is related to the possibility of monitoring these new materials and treatments as, to date, no significant contributions have been made yet towards the state of the art.

Raquel Bayón, head of the Tribology Unit at Tekniker says that “In hostile and ever-changing environments where offshore wind power infrastructures operate, continuous coating condition monitoring is essential from the perspective of preventive maintenance actions for the main structure of a WTG that must be based on accurate and true information”.

This explains why efforts are currently underway out to develop a sensor that can deliver reliable on-site readings and measurements on coatings used in systems that require significant high-cost maintenance actions.

Bayón also adds “We have manufactured a sensor fitted with two interdigitised comb electrodes that can be installed in the coating itself, within the paint scheme of the WTG thanks to its small size and low cost. The device provides a source of reliable first-hand information on the condition of the protective layer covering offshore structures of this kind”.

On the other hand, and as regards multifunctional organic coatings, Tekniker has developed several base-paint solutions with better properties in terms of corrosion, tribocorrosion, super hydrophobicity, resilience and higher levels of adherence. As they dry quicker, on-site painting and repairs are facilitated and it becomes possible to guarantee greater durability for the different components installed aboard offshore facilities.

The Tekniker researcher also says “we have chosen and applied additive paint formulations with charges based on graphene and inorganic anti-corrosion pigments that offer very good corrosion resistance properties. These new coatings have been validated by running static immersion and cyclical corrosion tests according to ISO 12944 and at sea.

With regard to monitoring sensors, the AVANSURF initiative has confirmed their technical effectiveness for use in monitoring and prediction operations applied to the degradation of organic coatings in offshore applications to perform, minimise, optimise and programme maintenance actions.

Bayón concludes by stating “this technology must develop even further from the point of view of sensor design to ascertain how results must be interpreted to establish an accurate correlation with the degree of degradation found in different coating systems.

AVANSURF, a five-million-euro project that has ended this year, was included under the umbrella of the CIEN programme developed by the Centre for Technological and Industrial Development (CDTI) and the Spanish Ministry of Science and Innovation.

The project consortium is made up of the following industrial partners: ArcelorMittal, Colores Cerámicos de Tortosa (CCT), Industrial de Acabados (INDASA), Pinturas Hempel, Tadarsa Eólica, Sistem Car, Laboratorios Alpha San Ignacio Pharma (ALPHASIP). In addition to Tekniker, the project has involved other technological partners such as the Spanish National Research Council (CSIC) and the CTC technology centre.