Artificial intelligence to grow the market’s best bananas

The Tekniker technology centre is developing a tool that characterises bananas and optimises ripening processes within the framework of the eFOOD 4.0 project. The solution enables ripening technicians to offer consumers optimum products at any time of the year throughout the entire value chain.

Image processing based on neural networks is one of the AI techniques that is helping to develop solutions for sectors such as the food industry. It allows companies to detect errors in their production and processing lines and also improve the quality of their products in an objective manner and gives them a better understanding of the entire process.

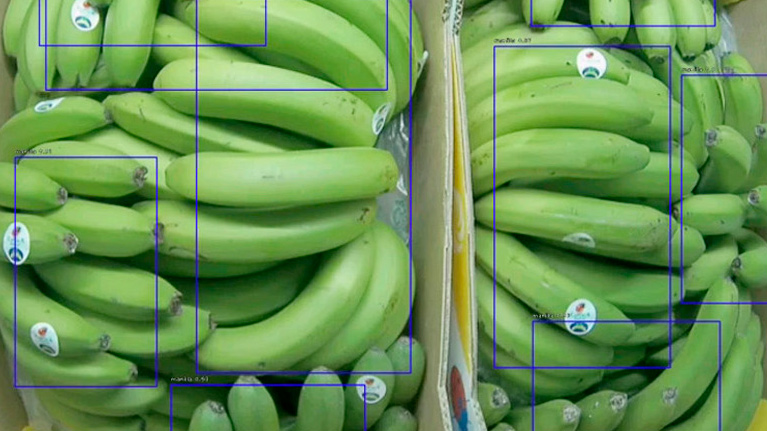

The Tekniker technology centre, a member of the Basque Research and Technology Alliance (BRTA) with extensive knowledge on how to use AI techniques such as Deep Learning, specifically CNNs (convolutional neural networks) for vision applications used to detect and identify objects and their characteristics, has developed an innovative tool within the framework of eFOOD 4.0 to characterise bananas and optimise their ripening process.

According to Aitor Gutiérrez, a Tekniker researcher, “we have developed a Deep Learning model that allows us to spot defects or blemishes via image processing based on artificial intelligence.

The process of creation followed for the Deep Learning model applied to banana characterisation involved the following steps: generating sets of images to be labelled (classified), applying data augmentation techniques, selecting adjustment architectures for hyper-parameters, model training model and, finally, evaluating results.

The final outcome is a “virtual analyst” that identifies banana features generated by more than 2,000 images obtained at the EUROBANAN LOGÍSTICA NORTE and GRUPO UVESCO facilities.

Tekniker has been responsible for pre-processing all data sets, “training” the AI model and commissioning the solution at GRUPO UVESCO’s facilities.

Better quality bananas at any time of the year

The end result is that it is possible to optimise the ripening of bananas and deliver offer top quality products regardless of the season by generating optimised ripening conditions that produce gains in terms of efficiency and reduce food waste.

Within the scope of eFOOD 4.0, work has also focused on automating the system so it can determine the degree of ripeness of each banana throughout the entire value chain.The process starts with the ripening chambers at EUROBANAN LOGÍSTICA NORTE and then proceeds towards to storage, distribution and sale logistics until the product reaches the end user in shops operated by GRUPO UVESCO.

Our “virtual analyst” assists ripening technicians in terms of decision making related to product management by monitoring bananas on a real time basis and obtaining estimates on how bananas evolve”, explains the Tekniker researcher.

The incorporation of 4.0 technologies featuring sensors, artificial vision capabilities and predictive models provide a better and far more objective monitoring system for the ripening process and a much better understanding of how the entire process works.

By analysing various parameters such as colour or the presence of blemishes and other features, EUROBANAN LOGÍSTICA NORTE and GRUPO UVESCO can offer end consumers top quality bananas throughout the year.

This e-FOOD 4.0 project in which, in addition to Tekniker, other partners such as EUROBANAN LOGÍSTICA NORTE and GRUPO UVESCO have been involved, has been funded by the Hazitek 2019-20 programme.