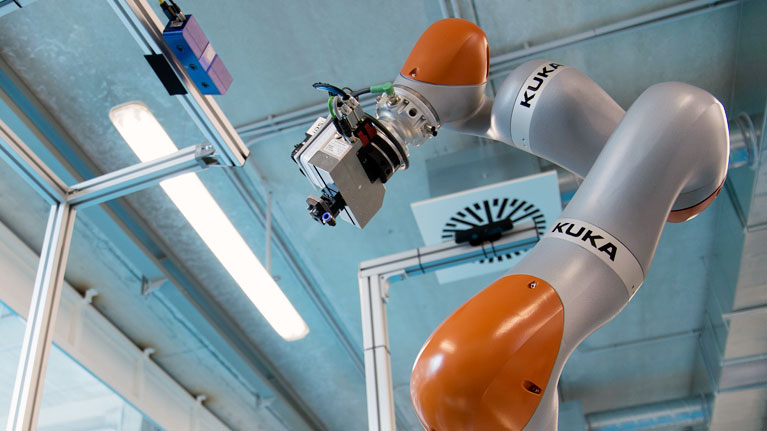

Collaborative robotics for aeronautical inspection

IK4-TEKNIKER is leading the European project CRO-INSPECT whose aim is to improve aircraft flap inspection practices by means of collaborative robotics and ultrasound techniques.

The incorporation of composite materials to the aeronautic business used to build lighter, less polluting and more energy-efficient aircraft requires that sophisticated inspection techniques be implemented for materials or parts in order to detect any potential failures by means of non-destructive testing.

With the ultimate aim of optimising these processes, the IK4-TEKNIKER technology centre is running a European project called CRO-INSPECT to improve flap inspection practices by incorporating robotics and advanced ultrasound techniques using guided waves. The project focuses on the requirements set forth by SAAB, a manufacturer of aeronautical components that needs to optimise inspection processes involving their components.

The need to opt for more sustainable and environmentally friendly aeronautics means that composite materials will be required together with a new focus in terms of inspection practices. Nowadays, stringent quality demands related to the aeronautical business require that 100% of the parts manufactured undergo inspections and this has repercussions in terms of reliability, efficiency and cost indices.

This project, that kicked-off in September 2016 and will finish August 2019, is focused on creating a hybrid working environment where human beings and robots may collaborate in inspection tasks by applying advanced ultrasound inspection techniques featuring guided waves that will allow defects to be detected in those areas of components that are hard to visualise and reach.

In addition to IK4-TEKNIKER, the project leader, the consortium responsible for running the project is formed by IK4-LORTEK and a company called TECNATOM, specialised in inspection services and structural component integrity.

The main goals of the project are focused on developing a number of technological components to monitor the robotics platform, safety and inspection. The final outcome will deliver a safe collaborative inspection solution needed to perform reliable and efficient flap inspections.

In this way, it will be possible to substantially upgrade the quality of inspection work involving large components and to perform quicker and more reliable inspections improving investment returns.

Consequently, it is expected that verification cycles will be cut by up to 40%. Participants in this project have received funds totalling 350,000 from the European Union.

IK4-TEKNIKER’s contribution

IK4-TEKNIKER will lead all activities related to collaborative robotics for the purpose of to generating safe interactive environments between human beings and robots.

The Basque technology centre is a benchmark organisation in terms of research and design actions related to a new generation of smart, stand-alone robots designed to deliver reliability, speed and flexibility in industrial environments.

The organisation has a significant amount of experience with regard to other European projects such as X-ACT, SME-Robotics, ROBOPARTNER, EUROC Challenges and MAINBOT that have allowed the company to address the challenges arising from the project in terms of collaborative robotics.

The advantages of collaborative robotics

The know-how used for collaborative work manner that will be applied in CRO-INSPECT enhances the solution’s resilience. On the one hand, the robot will be able to operate in a fully autonomous manner, a functionality that will make it possible to further improve reliability and inspection cycles.

On the other, the solution will allow technicians to perform even the most complex operations more efficiently by using robots as supporting tools.