Control in use of industrial fluids

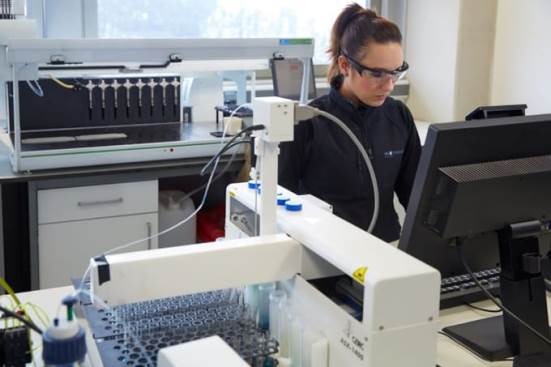

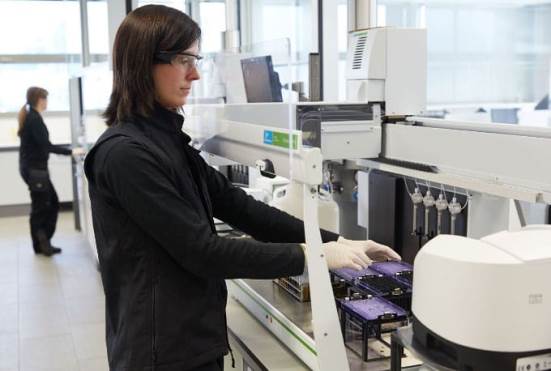

Through the monitoring of the physicochemical, thermal and tribological properties of the industrial fluids not only can the quality of the fluid be determined but also the status of the machine can be diagnosed in a comprehensive manner and strategies for plant maintenance can be established in accordance with the condition.

At TEKNIKER the control in the use of industrial fluids has as its objective the diagnostics of fluids for predictive maintenance of lubricating oils and greases, dielectrics, coolants and fuels.

The main areas of work are:

1- Characterisation of high heat transfer (HTF and molten salts) and low temperature (cooling) fluids for various applications:

- HVAC systems

- Solar thermal plants

- Heat exchangers

2- Development and improvement of industrial fluids through selective additives

- Nanoparticles

- Ionic Liquids

3- In such diverse fluids as

- HTF

- molten salts

- Dielectrics

- Lubricants

- Greases

- Refrigerants

4- Development and refinement of advanced characterisation techniques in response to new fluids entering the market

- Initiatives validated in benchmark groups such as AENOR and comparison studies with other laboratories.

Related contents

- Array ( [id] => 43 [idcategoria] => 2 [idsubcategoria] => [imagen] => 09_AI_IS_Control_Uso_Fluidos_Industriales.jpg [caso_exito_1] => 56 [caso_exito_2] => [caso_exito_3] => [cliente_1] => [cliente_2] => [cliente_3] => [direcciones_email] => consultasweb@tekniker.es [titulo] => Control in use of industrial fluids [video] => [texto_1] =>

- HVAC systems

- Solar thermal plants

- Heat exchangers

- Nanoparticles

- Ionic Liquids

- HTF

- molten salts

- Dielectrics

- Lubricants

- Greases

- Refrigerants

- Initiatives validated in benchmark groups such as AENOR and comparison studies with other laboratories.

- Multi-elemental analysis of oil samples

- Quick analysis

- Minimisation of soot accumulation

- Reduction to the minimum of equipment maintenance

- Determines the content in metals of wear, contamination and additives present in lubricating oils and greases

- Arm with eight tips which dispense simultaneously for multi-tip processing from the sample vials to the test tubes

- Quick analysis

- Range of up to 384 samples per batch

- Precise pipetting and optimal performance

- Preparation of liquid samples with high capacity and performance

- Up to 100 samples analysed per hour with OilExpress 4 DUO or up to 384 in one batch without the need for attendance

- Significant savings, compared with similar systems, by reducing solvent residues, thanks to the intelligent cleaning system (up to 80% or more)

- Results under the most common standards such as ASTM or JOAP

- Allows analysis of a large numbers of samples of oil per day, even highly viscous samples

- Modular construction of one bath with two viscometers per bath

- System of variable temperature selection from 20°C to 100°C

- Viscosity range from 0.5 to 5000 cSt

- Complies with the precision of ASTM D 445

- The equipment measures up to eight samples per hour with standard tubes and up to 15 with fast tubes (fast run)

- The equipment is designed to work unattended, given it has carousels for 50 samples per tube (100 per bath)

- The results of kinematic viscosity are provided completely automatically, meeting the specifications of standard ASTM D 445

- Measures transparent, dark and opaque liquids

- The GX-271 automatic changers allow up to 80 samples per changer in just one batch

- They can make up to 160 valuations per batch, unattended

- Parallel valuation

- Conditions in functions of the method

- Temporary memory of results

- Series sequence

- Automatic titrator which allows two titrations to run in parallel and independently of each other

- The morphological analysis is carried out automatically based on an intelligent neural network system

- Chamber for detecting and determining the number and morphology of the particles

- No calibration required, a fluid pattern verification is sufficient

- Eliminates from the result any particles of air and water bubbles that may be present in the fluid

- The different ISO, NAS, NAVAIR, etc. classifications can be reported

- It facilitates automation and increases productivity, being able to perform hundreds of samples daily, unattended

- Executes a particle count in lubricating oils, as well as the study of the morphology and distribution of the wear and/or contamination particles in the oil

- Performing the titration using an oven avoids a lot of potential contaminants entering in the titration cell

- Its high degree of automation facilitates working in unattended mode

- Equipment which determines the water content in oils in an optimal range between 10 to 10000 ppm

- Easy handling and execution of thermometric titration by incorporating intuitive titration software

- An alternative to other analytical techniques which are difficult or which give titration problems

- Fast results (less than one minute)

- No sensor calibration required

- The sensor does not need maintenance

- Equipment for samples for which a large enough temperature change occurs in the reaction in the sample solution

- It is especially suitable in titrations for which other techniques are difficult to perform, especially in certain types of synthetic oils or complicated packages of additives

- Range of up to 100 samples per batch

- The sample consumption is very low, around 10-15 ml

- No need to weigh or measure the sample volume because the equipment performs the dilution defined in the method

- It allows automatic sample dilution in the event of analysing very viscous samples (>320 cSt)

- The calibration is in accordance with current standards (ISO 4406)

- Size range: 4 µm(c) to 70 µm(c) (8 size channels: 4, 6, 10, 14, 21, 25, 38, 70 µm(c))

- Particle counting system for any type of oil: hydraulic, gear, lubricating, etc.

- The software makes it possible to obtain the different CIE ΔE, a, b and L values, as indicated in the recently published ASTM standard

- With the help of UV-Vis-NIR laboratory equipment, the tendency to form varnish (MPC) can be determined for a wide variety of oils

- Temperature scale: ambient temperature – 500/700ºC

- Heating rate: 0.1-50 K/min

- Pressure range: 0-10 MPa

- Gas flow: Freely selectable; precise control of purge gas flow and total pressure with an external controller

- Atmosphere: Measurements under different atmospheres: inert, oxidising, reducing, reactive...

- Using the high pressure differential scanning calorimeter, the onset (or start point) of an oil degradation can be determined. In this way, the remaining useful life of the oil can be evaluated

- Determines the level of soot present in the oil

- Predicts its thermal and/or oxidative stability, even at high temperatures (800-1000º C)

- Determines the volatile, humidity, content etc.

- Study of the behaviour of different oil formulations: whether they gain or lose weight due to decomposition, oxidation or dehydration

- Evaluates how the change occurs en masse of both new and used oils under controlled heating conditions

- Software with menus (Orchestrator Software)

- Viscosity range: 10-3 to 104 Pa.s

- Stability range 10-3 to 102 rad/s

- Dynamic range 10-5 to 102 rad/s

- Torque from 2×10-7-102 mN.m

- Rheometry helps in understanding the rheological properties (viscoelasticity, shear rate, etc.) or behaviour of both oils and lubricating greases based on pressure, temperature, shear rate, etc.

- The ARES-RFS rheometer is configured either with the Peltier or with the temperature control of recirculating bath option. Both environmental control systems are easily interchangeable, where necessary. Because the torque is measured separately, the ARES-RFS is able to provide inertia-free dynamic measurements of structured low viscosity fluids over a wide range of frequencies, independent of the viscosity of the material

- High resolution (~100 Å)

- Large depth of field

- Realisation of chemical analysis in small areas: intermetallic, precipitated, contaminant, particle, etc. phases.

- Simple preparation of samples

- Observation and surface characterisation of inorganic and organic materials, providing morphological information of the material analysed

Through the monitoring of the physicochemical, thermal and tribological properties of the industrial fluids not only can the quality of the fluid be determined but also the status of the machine can be diagnosed in a comprehensive manner and strategies for plant maintenance can be established in accordance with the condition.

[fase_1] => [fase_2] => [fase_3] => [fase_4] => [texto_2] =>At TEKNIKER the control in the use of industrial fluids has as its objective the diagnostics of fluids for predictive maintenance of lubricating oils and greases, dielectrics, coolants and fuels.

The main areas of work are:

1- Characterisation of high heat transfer (HTF and molten salts) and low temperature (cooling) fluids for various applications:

2- Development and improvement of industrial fluids through selective additives

3- In such diverse fluids as

4- Development and refinement of advanced characterisation techniques in response to new fluids entering the market

CHARACTERISTICS OF THE EQUIPMENT

EXPERTISE

) [1] => Array ( [id] => 39 [titulo] => JANUS® Automated auto-thinner [imagen] => Autodiluidor_Automatizado_JANUS.jpg [texto] =>

CHARACTERISTICS OF THE EQUIPMENT

EXPERTISE

CHARACTERISTICS OF THE EQUIPMENT

EXPERTISE

CHARACTERISTICS OF THE EQUIPMENT

EXPERTISE

CHARACTERISTICS OF THE EQUIPMENT

EXPERTISE

CHARACTERISTICS OF THE EQUIPMENT

EXPERTISE

CHARACTERISTICS OF THE EQUIPMENT

EXPERTISE

CHARACTERISTICS OF THE EQUIPMENT

EXPERTISE

CHARACTERISTICS OF THE EQUIPMENT

EXPERTISE

CHARACTERISTICS OF THE EQUIPMENT

EXPERTISE

CHARACTERISTICS OF THE EQUIPMENT

EXPERTISE

CHARACTERISTICS OF THE EQUIPMENT

EXPERTISE

CHARACTERISTICS OF THE EQUIPMENT

EXPERTISE

CHARACTERISTICS OF THE EQUIPMENT

EXPERTISE

Industrial sectors

Singular equipment

- ICP-OES Optima 7300 V Spectrometer

ICP-OES Optima 7300 V Spectrometer

CHARACTERISTICS OF THE EQUIPMENT

- Multi-elemental analysis of oil samples

- Quick analysis

- Minimisation of soot accumulation

- Reduction to the minimum of equipment maintenance

EXPERTISE

- Determines the content in metals of wear, contamination and additives present in lubricating oils and greases

- JANUS® Automated auto-thinner

JANUS® Automated auto-thinner

CHARACTERISTICS OF THE EQUIPMENT

- Arm with eight tips which dispense simultaneously for multi-tip processing from the sample vials to the test tubes

- Quick analysis

- Range of up to 384 samples per batch

- Precise pipetting and optimal performance

EXPERTISE

- Preparation of liquid samples with high capacity and performance

- FTIR OilExpress 4

FTIR OilExpress 4

CHARACTERISTICS OF THE EQUIPMENT

- Up to 100 samples analysed per hour with OilExpress 4 DUO or up to 384 in one batch without the need for attendance

- Significant savings, compared with similar systems, by reducing solvent residues, thanks to the intelligent cleaning system (up to 80% or more)

- Results under the most common standards such as ASTM or JOAP

EXPERTISE

- Allows analysis of a large numbers of samples of oil per day, even highly viscous samples

- CAV® 2000 Automatic viscometer

CAV® 2000 Automatic viscometer

CHARACTERISTICS OF THE EQUIPMENT

- Modular construction of one bath with two viscometers per bath

- System of variable temperature selection from 20°C to 100°C

- Viscosity range from 0.5 to 5000 cSt

- Complies with the precision of ASTM D 445

- The equipment measures up to eight samples per hour with standard tubes and up to 15 with fast tubes (fast run)

EXPERTISE

- The equipment is designed to work unattended, given it has carousels for 50 samples per tube (100 per bath)

- The results of kinematic viscosity are provided completely automatically, meeting the specifications of standard ASTM D 445

- Measures transparent, dark and opaque liquids

- TAN/TBN T90 baloratzaileak GX-271 lagingailu automatikoekin

TAN/TBN T90 baloratzaileak GX-271 lagingailu automatikoekin

CHARACTERISTICS OF THE EQUIPMENT

- The GX-271 automatic changers allow up to 80 samples per changer in just one batch

- They can make up to 160 valuations per batch, unattended

- Parallel valuation

- Conditions in functions of the method

- Temporary memory of results

- Series sequence

EXPERTISE

- Automatic titrator which allows two titrations to run in parallel and independently of each other

- LNF Q200 Particle Counter

LNF Q200 Particle Counter

CHARACTERISTICS OF THE EQUIPMENT

- The morphological analysis is carried out automatically based on an intelligent neural network system

- Chamber for detecting and determining the number and morphology of the particles

- No calibration required, a fluid pattern verification is sufficient

- Eliminates from the result any particles of air and water bubbles that may be present in the fluid

- The different ISO, NAS, NAVAIR, etc. classifications can be reported

- It facilitates automation and increases productivity, being able to perform hundreds of samples daily, unattended

EXPERTISE

- Executes a particle count in lubricating oils, as well as the study of the morphology and distribution of the wear and/or contamination particles in the oil

- Content in water K.F. Coulometric 851

Content in water K.F. Coulometric 851

CHARACTERISTICS OF THE EQUIPMENT

- Performing the titration using an oven avoids a lot of potential contaminants entering in the titration cell

- Its high degree of automation facilitates working in unattended mode

EXPERTISE

- Equipment which determines the water content in oils in an optimal range between 10 to 10000 ppm

- Thermometric Titrator 859

Thermometric Titrator 859

CHARACTERISTICS OF THE EQUIPMENT

- Easy handling and execution of thermometric titration by incorporating intuitive titration software

- An alternative to other analytical techniques which are difficult or which give titration problems

- Fast results (less than one minute)

- No sensor calibration required

- The sensor does not need maintenance

EXPERTISE

- Equipment for samples for which a large enough temperature change occurs in the reaction in the sample solution

- It is especially suitable in titrations for which other techniques are difficult to perform, especially in certain types of synthetic oils or complicated packages of additives

- CiNRG Particle Counter

CiNRG Particle Counter

CHARACTERISTICS OF THE EQUIPMENT

- Range of up to 100 samples per batch

- The sample consumption is very low, around 10-15 ml

- No need to weigh or measure the sample volume because the equipment performs the dilution defined in the method

- It allows automatic sample dilution in the event of analysing very viscous samples (>320 cSt)

- The calibration is in accordance with current standards (ISO 4406)

- Size range: 4 µm(c) to 70 µm(c) (8 size channels: 4, 6, 10, 14, 21, 25, 38, 70 µm(c))

EXPERTISE

- Particle counting system for any type of oil: hydraulic, gear, lubricating, etc.

- Trend Measurement in the formation of varnishes (MPC) V-570

Trend Measurement in the formation of varnishes (MPC) V-570

CHARACTERISTICS OF THE EQUIPMENT

- The software makes it possible to obtain the different CIE ΔE, a, b and L values, as indicated in the recently published ASTM standard

EXPERTISE

- With the help of UV-Vis-NIR laboratory equipment, the tendency to form varnish (MPC) can be determined for a wide variety of oils

- HP-DSC 1

HP-DSC 1

CHARACTERISTICS OF THE EQUIPMENT

- Temperature scale: ambient temperature – 500/700ºC

- Heating rate: 0.1-50 K/min

- Pressure range: 0-10 MPa

- Gas flow: Freely selectable; precise control of purge gas flow and total pressure with an external controller

- Atmosphere: Measurements under different atmospheres: inert, oxidising, reducing, reactive...

EXPERTISE

- Using the high pressure differential scanning calorimeter, the onset (or start point) of an oil degradation can be determined. In this way, the remaining useful life of the oil can be evaluated

- TGA/DSC 1

TGA/DSC 1

CHARACTERISTICS OF THE EQUIPMENT

- Determines the level of soot present in the oil

- Predicts its thermal and/or oxidative stability, even at high temperatures (800-1000º C)

- Determines the volatile, humidity, content etc.

- Study of the behaviour of different oil formulations: whether they gain or lose weight due to decomposition, oxidation or dehydration

EXPERTISE

- Evaluates how the change occurs en masse of both new and used oils under controlled heating conditions

- RFS3 Rheometer

RFS3 Rheometer

CHARACTERISTICS OF THE EQUIPMENT

- Software with menus (Orchestrator Software)

- Viscosity range: 10-3 to 104 Pa.s

- Stability range 10-3 to 102 rad/s

- Dynamic range 10-5 to 102 rad/s

- Torque from 2×10-7-102 mN.m

EXPERTISE

- Rheometry helps in understanding the rheological properties (viscoelasticity, shear rate, etc.) or behaviour of both oils and lubricating greases based on pressure, temperature, shear rate, etc.

- The ARES-RFS rheometer is configured either with the Peltier or with the temperature control of recirculating bath option. Both environmental control systems are easily interchangeable, where necessary. Because the torque is measured separately, the ARES-RFS is able to provide inertia-free dynamic measurements of structured low viscosity fluids over a wide range of frequencies, independent of the viscosity of the material

- Scanning Electron Microscope (SEM)

Scanning Electron Microscope (SEM)

CHARACTERISTICS OF THE EQUIPMENT

- High resolution (~100 Å)

- Large depth of field

- Realisation of chemical analysis in small areas: intermetallic, precipitated, contaminant, particle, etc. phases.

- Simple preparation of samples

EXPERTISE

- Observation and surface characterisation of inorganic and organic materials, providing morphological information of the material analysed