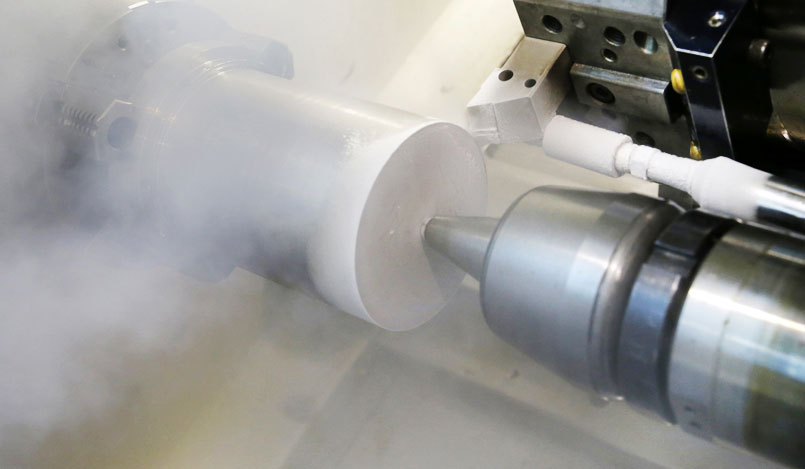

Cryogenic machining of 50CrMo4 (58 HRc) steel

Enhancing the useful life of the tool and obtaining a more gradual wear process.

Increasing the duration of the cutting tool by more than 25 times, using liquid nitrogen as refrigerant.

With mill roughing of hardened steel, excessive tool consumption occurs, causing faults due to fracture of the cutting edge. This, amongst other drawbacks, involves much lost (“dead”) time during machining.

The principal objective is to change the mechanism of wear so as to be more gradual and, at the same time, lengthen the life of the tool for increasing the performance of the operation.

The solution put forward involves using liquid nitrogen as a cryogenic refrigerant. After an optimisation process of the cryogenic refrigeration system, wear through abrasion was achieved, as well as the increase in the duration of the cutting tool by more than 25 times.

Also, the use of liquid nitrogen contributes to machining that is more ecological, given that it does not generate contamination or waste.