Digital technologies to advance towards new zero-defect manufacturing systems

Zero-defect manufacturing is increasingly resorting to digital technologies to meet very demanding requirements posed by manufactured parts. The REDAMP project, in which Tekniker is currently involved, is developing digital technologies to improve manufacturing processes based on additive manufacturing.

Nowadays, zero-defect manufacturing or ZDM is one of the main targets in the area of advanced manufacturing. The quality of industrial products depends on the reliability of the equipment used and on the stability of the manufacturing and repair processes involving parts and components. Machine or process faults can produce imperfections in the end product.

It is within this context that the so-called REDAMP initiative has taken centre stage. A project in which Tekniker, a member of the Basque Research and Technology Alliance, is currently involved and whose main goal is focused on applying early digital fault detection technologies so repairs can be carried out immediately during advanced manufacturing processes based on directed energy deposition (DED), to avoid wasting material and enable the certification of DED parts for high added value structural applications in different sectors.

More specifically, the project has focused on developing advanced monitoring techniques integrated in manufacturing processes, defect detection technologies featuring non-destructive testing NDT and artificial intelligence applied to DED processes. The ultimate goal is to improve the quality of parts by consuming less materials and ensuring that only defect-free parts are produced.

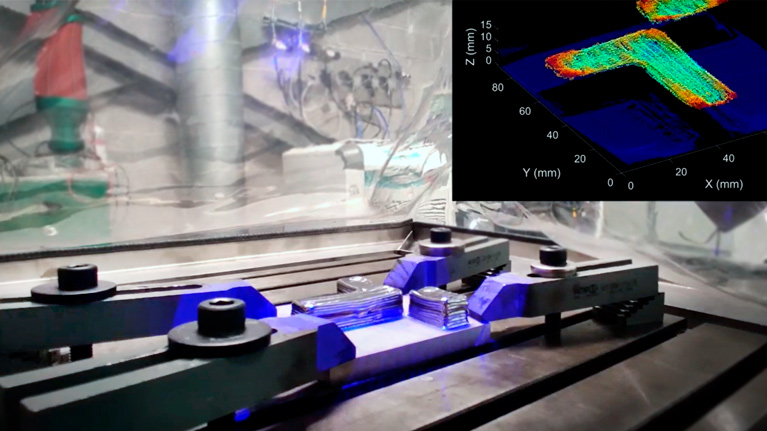

In order to achieve this goal, an infrastructure has been developed to gather, process and analyse process data (vision sensors, 3-D sensors, machine data, process parameters, end-quality data).

Thanks to the experience and knowledge generated by Laser Cladding or Laser Metal Deposition (LMD) techniques and process control and monitoring techniques incorporating metrology measuring and artificial vision systems, Tekniker has contributed to the project by applying data analytics and monitoring techniques equipped with laser-based DED processes, specifically in the LMD process.

These data analysis and monitoring solutions will deliver more robust additive manufacturing processes. It also explains why the project is focused on generating products with augmented quality for end users and on improving manufacturing systems currently deployed companies producing machines and additive manufacturing equipment.

In short, it is a must to advance towards new zero-defect manufacturing systems and increase the reliability of industrial manufacturing processes to achieve optimum results when manufacturing parts.

Click below to watch the videos

-Hand eye cali-In process 3D scanning in a directed energy depositionbration procedure of 3D scanner mounted on a directed energy deposition head