Hydrogen, a key element for decarbonisation

Climate change is currently one of the main challenges society must cope with to reduce carbon dioxide emissions drastically. Consequently, an energy transition is also required to replace fossil fuels with renewables. In this regard, renewable hydrogen will eventually become one of the main energy vectors needed to carry out said energy transition efficiently.

Hydrogen production with renewables is based on water electrolysis, a process that splits water molecules into their components (hydrogen and oxygen) by the electricity supplied by renewables. Electrolysis allows large amounts of renewable electric power to be stored over long periods of time by transforming electric power directly into hydrogen.

This is why electrolysis systems, also known as electrolysers, must be installed at photovoltaic and wind power farms. Electrolysers, however, do not only provide electrical power storage capabilities that increase the amount of power generated by renewables, but can also deliver grid frequency control and balancing capabilities.

As regards the different types of electrolysers that are currently available, those featuring polymeric membranes (PEMWE) have become increasingly relevant over the last decade as they are considered to be optimum for use with intermittent renewables thanks to features such as a rapid dynamic response, the possibility of operating at high current densities associated with high levels of efficiency, compact designs and the option of running at high pressure settings. The full potential this technology has been demonstrated in a few pilot projects such as the 2 MW Haeolus project or the 10 MW Refhyne project.

Although PEM electrolysers offer numerous advantages, there are still many obstacles hindering a widespread deployment of this technology in the market for power to hydrogen solutions. Such barriers are mainly due to high capital (CAPEX) and operating (OPEX) costs, to the absence of mass manufacturing processes and because there is a dependence on certain critical materials.

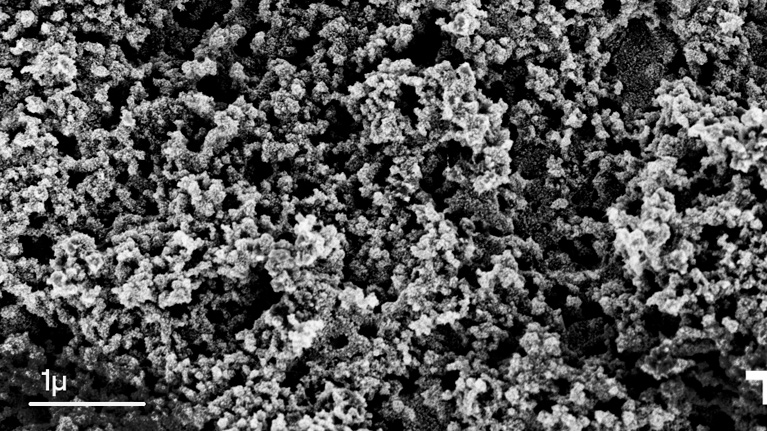

Consequently, new designs must be developed to allow electrolysis cells to incorporate cheaper materials with a view to implementing competitive serial manufacturing practices. New designs must also improve efficiency and increase system robustness by improving management actions associated with gas/water flows and thermal issues. New designs and materials should make it possible to increase operating pressure and produce more active cell surfaces.

It is within this particular context that Tekniker experts are currently working to develop new critical components to reduce manufacturing costs for the PEM electrolysis technology.

These new developments do not only focus of electrolysis systems, but also incorporate new integration and control technologies to achieve a perfect degree of coupling between electrolysers and renewable power facilities so that renewable hydrogen can be produced at competitive prices.

As hydrogen technologies must be deployed rapidly to achieve pre-established carbonisation goals, any knowledge acquired must be transferred to the industrial sector. This is why Tekniker is a member of the Basque Hydrogen Corridor (BH2C), an initiative where the expertise and efforts of a number of companies and organisations converge and whose ultimate goal is to transform renewables into a reality in the energy sector.

Download the paper in full.