IK4-TEKNIKER participates in a seminar on reliability organised by AEM

During this seminar, the technology centre will give a paper on how to develop technology to learn more about equipment behaviour and operation from the very beginning to achieve maximum in-use performance.

IK4-TEKNIKER will participate in the “1st Seminar on Reliability in Maintenance”, organised by AEM (the Spanish Maintenance Association) to be held in Madrid on November 27-28. Discussions will focus on a number of techniques currently in use to improve maintenance practices in the industry by measuring basic parameters such as reliability and availability.

The technology centre will bring its expertise to the conference on November 27 by giving a paper entitled “Learning to predict: How in-use behaviour can be modelled”. Industry 4.0 as well as data acquisition and communication technologies are nowadays enabling us to make further progress in terms of developing tools for Machine Learning and analytics with the support of AI and Big Data platforms to carry out predictive maintenance on equipment and achieve enhanced operational reliability.

Reality shows, however, that predicting is not an easy task for the industry as it is directly linked to knowing more about component wear and how in-use processes perform in terms of the equipment used.

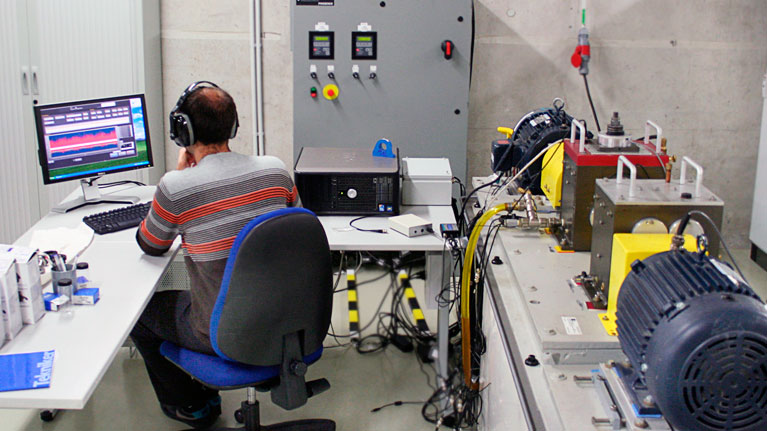

IK4-TEKNIKER is currently using state-of-the- art technology on the test benches available at the technology centre’s facilities to predict equipment status.

Specifically, the technology centre is now developing a platform within the framework of the European project i-Tribomat that provides analytics for data extracted from test benches. The platform provides testing traceability, context data and sensor signals so that analyses can be performed and knowledge can be drawn from tested components.

The ultimate goal, in short, is to make the most of the design stage to learn more about how equipment operates from the early stages, to use test benches to better understand their operations and even degrade them to discover their reliability and characteristic wear (fatigue) patterns. The aim is to extract knowledge and information from data that can be applied to equipment already in operation.

Further information

For further information, please visit the web site of the reliability seminar.