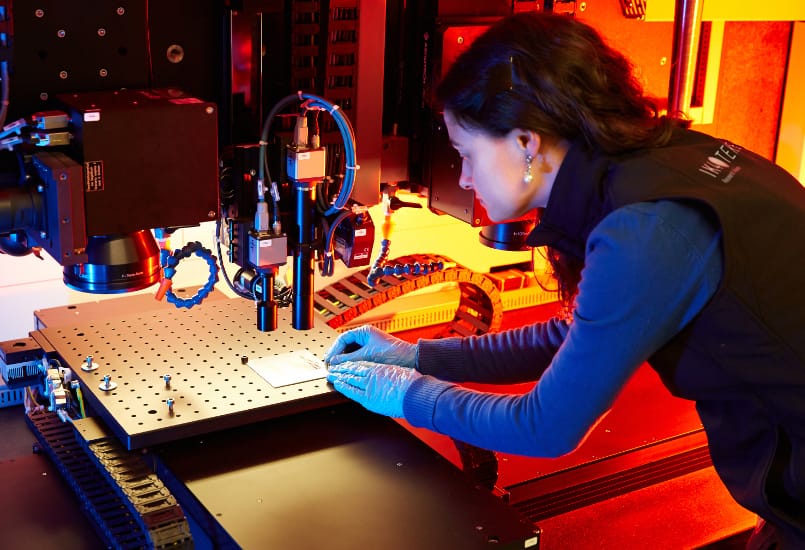

Laser microprocessing

TEKNIKER is specialised in the microprocessing of materials using laser technology applied to various sectors in industry. Laser microprocessing is primarily applied to any kind of component and tool - metallic, ceramic, or polymer - and which, depending on their optical properties, together with the laser itself, enable producing different effects.

The field of laser microprocessing involves different methods of manufacture, such as microstructuring, marking, drilling, etc., which take place at a micrometric scale and are applied to a wide range of materials, in order to improve and/or manufacture determined components and devices. TEKNIKER has been working for many years on the processing of precision materials, employing pulsed laser sources with different wavelength emissions, with a high-quality beam and short and ultra-short pulses. The goal is to process all types of materials and obtain good finishes, minimising thermal effects and the formation of burrs, while obviating the need for post-processing.

The experience and knowhow at TEKNIKER focus mainly on the following processes:

Micromachining: selective elimination of material using high-energy laser beams to create the geometry desired on any given substrate.

Marking: modification of the surface of a material using a laser beam, generating a visibly contrasted mark in the form of alphanumerical characters, drawings and images.

Drilling: generation of tapped holes in components of up to 1 mm thickness, of various geometries and at high processing speeds, using high-frequency pulsed laser beams with pulse repetition.

Texturising: involves the generation of micrometric patterns applied to the surface of a material with the goal of enhancing its properties (tribological, hydrophobic, etc.).