Machining

The aim is to develop and optimise the removal of machined material in order to obtain greater productivity and/or quality of the machined part. To this end, the process is tackled from various perspectives: the cutting tool itself, refrigeration/lubrication, the machine-tool, cutting conditions, the machining strategy and the material being machined. The process was studied experimentally as well as through modelling and simulation.

Machining is an established technology. Nevertheless, the ongoing evolution of the industry often involves the use of new materials or more exigent quality and environmental requirements. To meet these new challenges, TEKNIKER has embarked on experimentation, modelling and simulation, as well as on the implementation of other technologies to complement or enhance the process.

Some machining processes in which research has been undertaken are:

- Ecological machining (dry, MQL, cold air, cryogenic fluids: CO2 and liquid nitrogen

- Hard machining (hardened steels ~58HRc, hard metal, and so on)

- Aeronautics materials (Inconel 718, Ti6Al4V, gTiAl, etc.)

- Emerging materials (Mg, hybrids, ADIs, MMC, and so on)

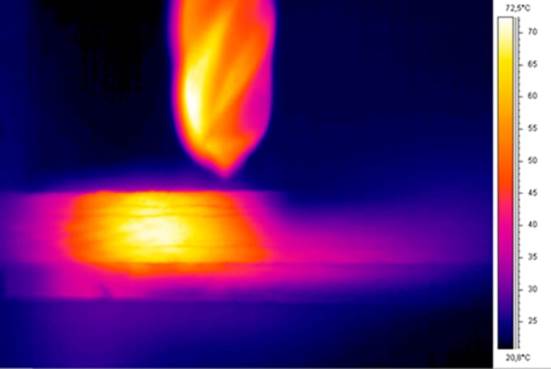

- Assisted processes (ultrasounds, high pressure refrigerant, laser, cryogenic refrigerant, etc.)

- In situ dimensional control

For the optimisation of machining it is necessary to control the variables of the process and know the loads to which the machine is being subjected in the cutting process. IK4-TEKNIKER has wide experience in the use of different means of monitoring, in carrying out the analysis of the machining process (measuring forces, power values, vibrations, temperature, generation of scarf, tool wear and tear, and so on).

Besides experimental characterisation, TEKNIKER uses machining simulation models, both in-house and commercial ones, for enhancing working conditions, cutting strategies and the cutting tool design. The simulation of the process enables forecasting the results prior to implementing the means of production, thus appreciably reducing experimental work.