Measuring capabilities incorporated to machine tools

The IK4-TEKNIKER technology centre is currently involved in the MH2020 project whose aim is to develop advanced measuring solutions to be incorporated to industrial manufacturing equipment.

In order to make progress in the development of more reliable, flexible and efficient manufacturing processes, the IK4-TEKNIKER technology centre is involved in a research and development project whose aim is to fit machine tools with high accuracy measuring systems to speed up production and improve the quality of large parts and components.

The so-called MH2020 initiative started last April and intends to meet requirements linked to boosting the competitiveness of the Basque industrial fabric by designing more efficient manufacturing equipment for sectors such as shipbuilding, aeronautics, power or automotion characterised by the production of large and highly accurate parts.

This three-year project is being carried out by a consortium made up of seven companies and five technology centres, members of the Basque Network of Science and Technology.

The ultimate goal of MH2020, a project led by a company called Juaristi, is to incorporate know-how and solutions allowing machine tools to measure with dimensional traceability and achieve greater precision throughout the entire work volume.

The IK4-TEKNIKER contribution

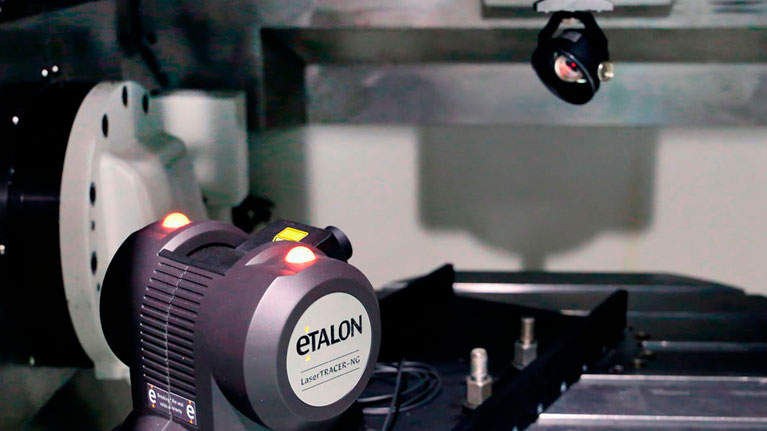

It is within this framework, that the Basque centre will provide its capabilities in terms of inspection and measurement. More specifically, research actions will focus on developing procedures allowing machine tool geometric and environmental conditions to be checked whilst running.

Work will also focus on the design and development of rapid and efficient checking procedures to reduce machine downtime and to devise calibration procedures for machining headers.

IK4-TEKNIKER researchers will develop and incorporate volumetric compensation solutions and also study thermal variations on large pieces of equipment as the main source of uncertainty during measuring processes.

In addition, uncertainties will be allocated to any measurements performed to obtain dimensional traceability and, together with other project partners, equipment will be fitted with massive dot acquisition sensors.

They will also be involved in development work related to hardware and software for machines designed to monitor and interpret information and successfully incorporate measuring systems.

In order to address these challenges, the technology centre will analyse and pay close attention to critical parameters affecting production process activities such as the size of a part or a machine tool or the type of measuring technology used.

A multiple consortium with only one goal

The MH2020 project is being carried out under the Hazitek 2016 Programme, funded by the Regional Ministry for Economic Development and Competitiveness of the Basque Government to support the implementation of R&D projects in the Basque Autonomous Community (BAC).

The initiative is being carried out by a consortium made up of the following companies: Juaristi, Goratu, Soraluce, Fagor Automation, Gometegui, Unimetrik and Ekide and members of the Basque Science, Technology and Innovation Nertwork: Innovalia Metrology, Aotek, Vicomtech-IK4 and IK4-IDEKO, together with IK4-TEKNIKER.

The Basque technology centre is cooperating in research & development activities with four of the seven companies involved in the project.