Mechatronic systems

Mechatronics is a discipline that includes the skills of mechanical engineering, electronics, control and automation, and computer technology, in order to design, develop, put into operation and optimize systems that operate in highly dynamic conditions with high precision, robustness and multi-actions.

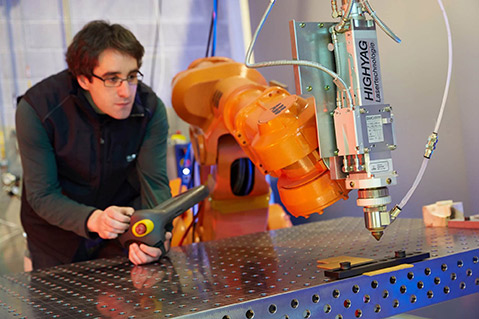

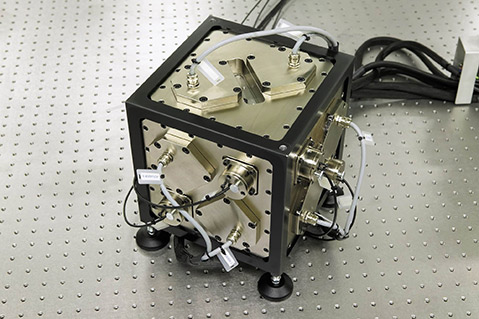

Tekniker is specialized in the design, development, manufacture and setting-up of complex mechatronic systems that require highly dynamic conditions with maximum precision in extreme conditions. These systems can be single action or multi-action The selection of the action, guiding and the measurement and control system is specific for each application, including, if necessary, the development of contact-free guiding systems using electro-magnetic levitation technology, special tools or any other required specifications.

The process starts with the generation of representative models of the system, adequate in complexity to each specification, and concludes with the experimental characterization of the system. If anything characterizes the models made by Tekniker, it would be the full correlation between the model-based simulations and the experimental results. This generation of models and simulation cycle is complemented by the following capabilities:

- Design and analysis of mechanisms

- Thermohydraulic design and analysis

- Design and analysis of controllers

- Design and analysis of drives, transmissions and guides

- Simulation of the machining process

- Fatigue calculation of components

- Design and analysis of magnetically levitated systems

The experimental test phase includes the following types of characterization:

- Static and dynamic characterization, vibration analysis

- Thermal characterization, deformations

- Geometric characterization, volumetric errors

These moulding and characterization capabilities can be applied in the development of any high performance equipment, from telescope components to energy storage systems and a further large variety of special machinery, with particular emphasis on new models of machine tools.

In this latter case, the modelling and simulation phase can even include, if required, the simulation of machining processes and their corresponding theoretical and/or experimental optimization (cutting conditions, tools, cutting fluids, machining trajectories):

- Milling, turning, grinding, drilling

- Micro-milling, micro laser machining, microEDM, micro-injection, micro-drilling

- Laser, ultrasounds, ECM, EDM

- Laser cladding for additive and repair manufacturing