New technologies to transform hydrogen storage

The aim of the DESSERT project is to revolutionise the energy transition with stainless steel piping to inject and extract hydrogen at underground reservoirs. Tekniker is playing a highly outstanding role in terms of performing advanced analyses and forecasting the behaviour of materials.

In the transition towards a future with cleaner energy, hydrogen has become an essential alternative to fossil fuels thanks to its capacity to store and transport energy efficiently and sustainably.

The storage of hydrogen in underground reservoirs, however, poses a number of technical challenges principally associated with the resistance and durability of the materials used for this purpose. In order to meet this requirement, it is essential to ensure that hydrogen will be able to play its role as a safe and accessible source of energy.

The main goal of the DESSERT project is to develop a new prototype of stainless steel piping joined by threaded connections to inject and extract hydrogen at underground reservoirs that will not only eventually become a feasible energy solution but also play a key role in the transition towards developing cleaner energy solutions.

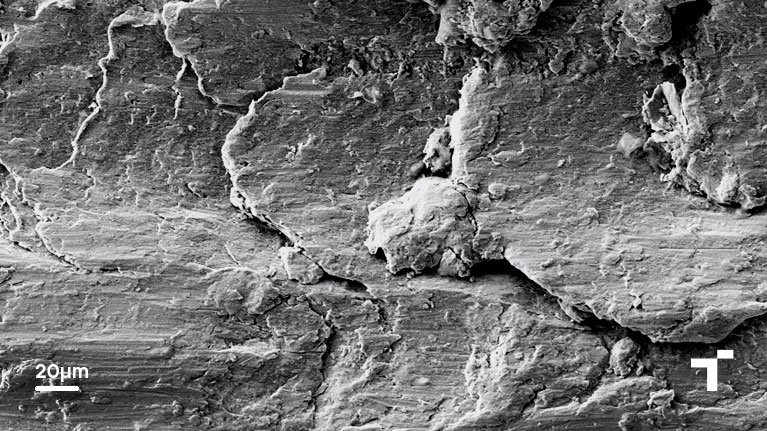

Tekniker is playing a fundamental role based on performing advanced analyses and predicting how materials behave in environments with high hydrogen content as well as by actively supporting the design and validation of new technological solutions developed in the project. The organisation will carry out specific studies to predict how steel behaves under static and dynamic conditions and address specific failure modes such as “galling”, i.e., severe wear involving threaded connections that also greatly affects the service life of the facilities where they are installed. Work of this kind will be essential to ensure that piping used to carry hydrogen meets the highest standards with regard to resistance and durability in demanding environments.

In addition to Tekniker, the project’s consortium comprises five partner organisations with an extensive amount of experience in the aforementioned areas that include steel manufacturers, universities, R&D centres and a consultancy firm specialised in research and innovation.

The DESSERT project has received funding from the European Union’s Research Fund for Coal and Steel (RFCS) programme under the GA No. 101157797.