Photonics transfers quality control from the laboratory to the production line

light!, the SECPHO technological journal has published a paper written by IK4-TEKNIKER addressing the development of sensoring devices applied to the agri-food business.

Developing advanced sensors represents a significant challenge as it requires an integration process for heterogeneous technologies that are becoming increasingly complex due to regulations currently in force, to the need to respond to operating conditions and to current market demands. Consequently, all of these devices must be connected, safe and cost-efficient; they must also be capable of operating autonomously and without supervision.

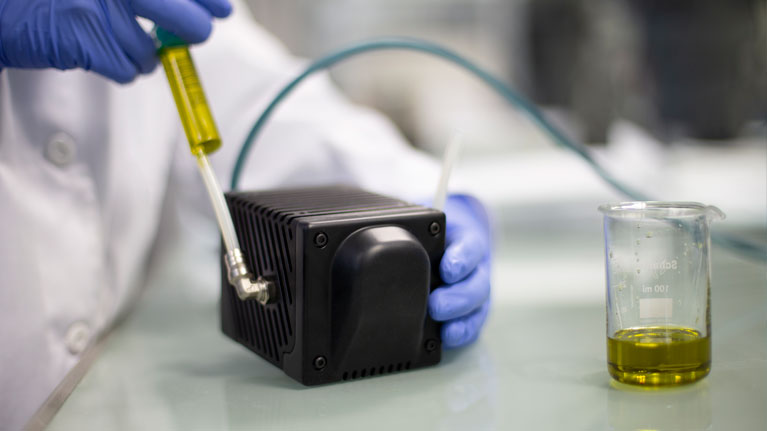

It is in this context that IK4-TEKNIKER is fitting sensor devices with photonic technologies to be used for on-line measuring applications in a number of industrial sectors, one of which is the agri-food business. The ultimate goal is to "transfer laboratory measurements to the point of interest” to obtain better process monitoring and quality control.

The paper entitled “Photonics transfers quality control from the laboratory to the production line” written by IK4-TEKNIKER and published in the third edition of light!, the SECPHO (Southern European Cluster in Photonics & Optics) journal explains how important and complex it is to develop advanced sensors and apply them to the agro-food business in a number of case studies.

Download the paper in full.