New technologies to make robotic product handling more flexible

Tekniker is leading HARTU project and will develop an artificial intelligence solution for robots to autonomously learn how to pick up previously unseen parts.

Automated product handling systems are effective when dealing with a small number of references and large production volumes. However, whenever operations involve a large variety of parts and low production volumes or delicate products, it could be complex and economically non-feasible to implement automated solutions.

HARTU, the European project coordinated by the Tekniker technology centre, will develop new technological solutions that enable robotic systems to operate with more resilience and versatility. The purpose of this initiative is focused on enhancing the ability of robots to efficiently handle a wide variety of products by introducing an Industry 5.0 environment and facilitating interactions between humans, robots and AI systems on production lines.

Iñaki Maurtua, Tekniker researcher and project coordinator, explains that “HARTU will address the need to handle a large number of parts of different sizes, shapes and characteristics and will introduce innovative learning concepts using AI techniques”.

More specifically, Tekniker will develop a solution based on AI, artificial vision and simulation so that the system itself can learn the best way to pick up the parts without having seen them previously.

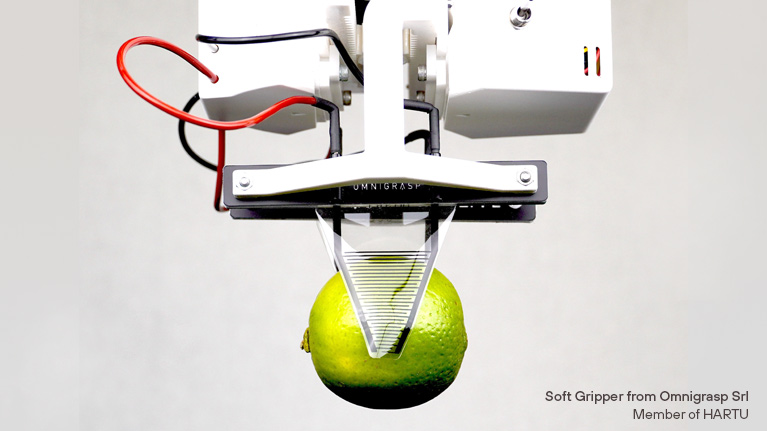

HARTU will also address the challenge of how to handle parts of different shapes and materials by means of a new gripper concept based on electro-adhesion technology that provides a high-adhesion force, exerting a minimum pressure, which reduces the risk of damaging the parts being handled.

The project also envisages the implementation of advanced force sensors and learning by demonstration techniques to deliver flexible and reconfigurable assembly systems.

Five real scenarios

The solutions offered by the HARTU project will be adapted to needs and realities in five manufacturing scenarios: automotive, household appliances, hand tools, the food sector and logistics. Tekniker will be responsible for three of the demonstrators.

One of the solutions will be used by TOFAS, a Turkish car manufacturer, to prepare orders, manage internal logistics and assembly; another solution will be developed with the Italian technology centre TCA to facilitate the sorting of fruit and vegetables at Centro Lazio, an Italian agricultural cooperative. The third case corresponds to preparing and palletising orders in different sectors where it is present the Basque technology provider ULMA, where handling operations involve a large number of references.

Finally, two industrial demonstrators for assembly processes will be developed, one for INFAR, a Taiwanese hand tool manufacturer, and the other to improve the reconfiguration capacity of Philips´ shaver production lines in the Netherlands.

With funding provided by the EU Horizon Europe programme, the HARTU initiative that kicked off in January 2023, will have a three-year duration.

In addition to Tekniker, the consortium has another 13 members from European Countries and Taiwan: the German Research Center for Artificial Intelligence (DFKI), the AIMEN technology centre, Politecnico di Bari University, the ITRI institute, and the companies Engineering Ingegneria Informatica, TOFAS, Philips, ULMA, Deep Blue, FMI HTS Drachten,, Tecnoalimenti, Infar Industrial, and Omnigrasp.