Surface engineering applied to hydrogen production

The Tekniker technology centre is applying advanced material deposition techniques within the framework of the H2BASQUE project to reduce manufacturing costs of components that are critical for the production of hydrogen.

The European Green Deal sponsored by the European Union to achieve climate neutrality by the year 20250 believes that green hydrogen is one of the key factors for decarbonisation to happen in EU countries. In fact, this strategy proposes that up to 6 GW of hydrogen be produced by 2024 and 40 GW by 2030 within the community.

One of the key technologies that could help to achieve the goals set in terms of hydrogen production is associated with the so-called PEM electrolysers that offer major advantages such as the degree of purity obtained in hydrogen and their ease of installation at renewable energy facilities. High manufacturing costs associated with the process and materials used, however, make it necessary to implement more affordable solutions instead of using catalysts based on precious metals.

The Tekniker technology centre, a member of the Basque Research and Technology Alliance (BRTA), with extensive experience in using these electrical systems to produce hydrogen, is currently working within the framework of the H2BASQUE project featuring an advanced material deposition technique called magnetron sputtering to minimise the amount of these precious metals as much as possible and reduce manufacturing costs for catalysts at an industrial scale although without diminishing efficiency and durability compared to those units currently on the market.

Critical components

Thanks to this technology, Tekniker can address two major challenges associated with reducing the amount of precious metals on these critical components and manufacturing catalysts that are related to reduce durability and less conversion efficiency.

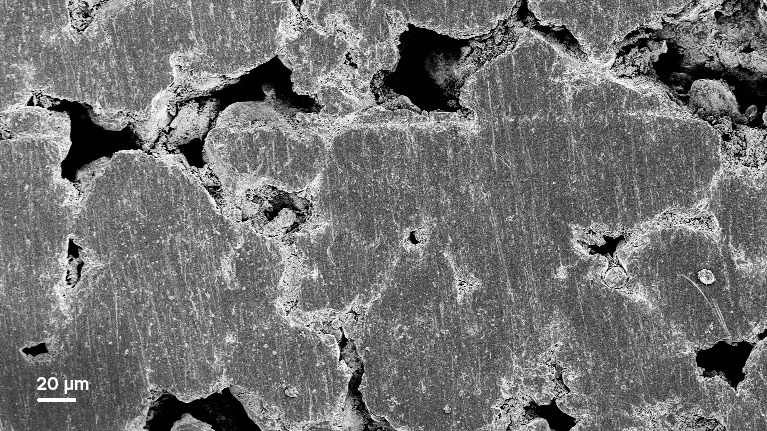

Eva Gutierrez, Coordinator of the Hydrogen Unit at Tekniker explains that “humid techniques are currently used to manufacture these catalysts to spray material on the electrodes, a technique that produces high levels of wastage. The magnetron sputtering technique, however, allows materials to be manufactured in a single pass with total composition and morphology control which means that materials can be deposited directly on electrodes without any kind of manipulation.

This means that it is now possible to manufacture catalysts containing less precious metals; a crucial feature, as these materials are very expensive and scarce.

Characterisation techniques will be used to evaluate Tekniker’s new developments to validate their use with regard to producing green hydrogen, clean energy and more decarbonisation once installed at renewable energy plants.

H2BASQUE (Technologies to Boost the Hydrogen Economy in the Basque Country) is an initiative funded by the Elkartek 2021 programme sponsored by the Basque Country that addresses the development of critical components and innovative technologies to generate green hydrogen. There are several universities, companies and technology centres of the Basque Country involved in this action.