Surface treatments: Heat and finish treatment

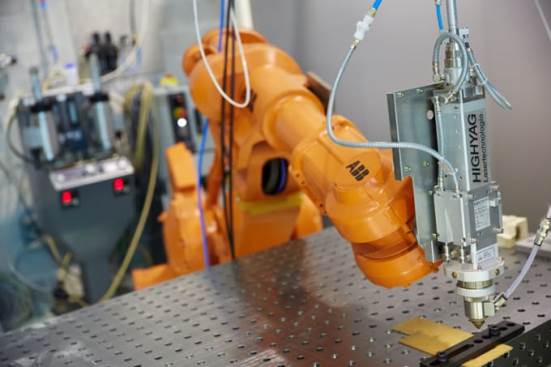

Thermal surface treatment and surface finish operations are a fundamental stage in a large number of sectors, such as the mould and matrix industry, the automobile and aeronautics sectors, medicine, optics, etc. The use of laser technologies in processes such as surface hardening, the cleaning or including the polishing of parts, bring many advantages: precision, flexibility in terms of viable geometries, facility for automation and control, and environmental sustainability.

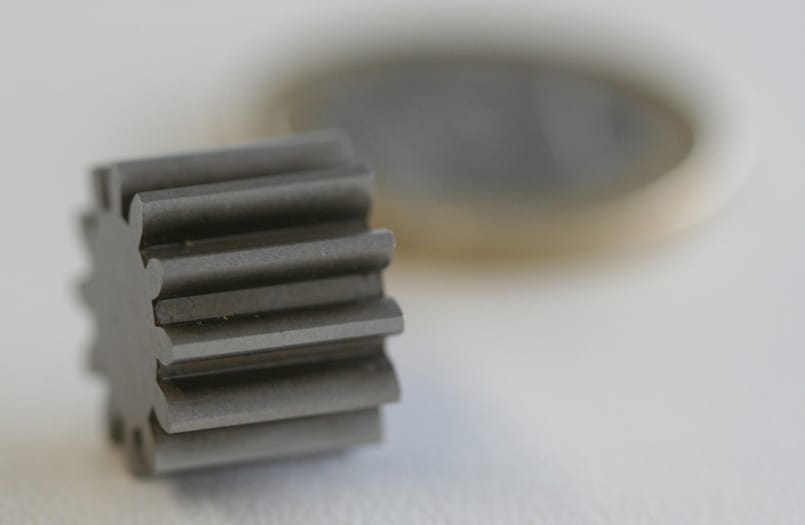

The most superficial structure of materials, such as their topography, has a fundamental influence on the response of the components to a multitude of parameters, such as their tribological behaviour, resistance to corrosion, biocompatibility, adhesion, reflectance, aesthetic appearance, etc. With the goal of adapting these properties to the specific functionality of each part, different industrial processes are currently employed, such as hardening and tempering, cleaning and polishing.

Surface hardening, normally following a tempering operation, is a heat treatment in which the part is rapidly cooled down from a temperature greater than that of austenisation, with the goal of conferring determined properties on it. Unlike conventional processes, hardening with laser produces minimum distortion and thermal affectation in the part. Neither does it need liquid refrigerant, given that the volume of the material itself enables dissipating the heat and cooling the part rapidly. The depth of the treatment, dependent on the material, is less than 2 mm, but it is easily controllable and reproducible depending on the parameters of the process.

Also, conventional surface cleaning technologies are based on mechanical, chemical or even combustion methods, which are aggressive for the substrate and harmful to the environment. In contrast, the use of laser technology provides a selective and precise tool that enables tackling the process in a clean and efficient manner.