The bin-picking technology for industrial solutions

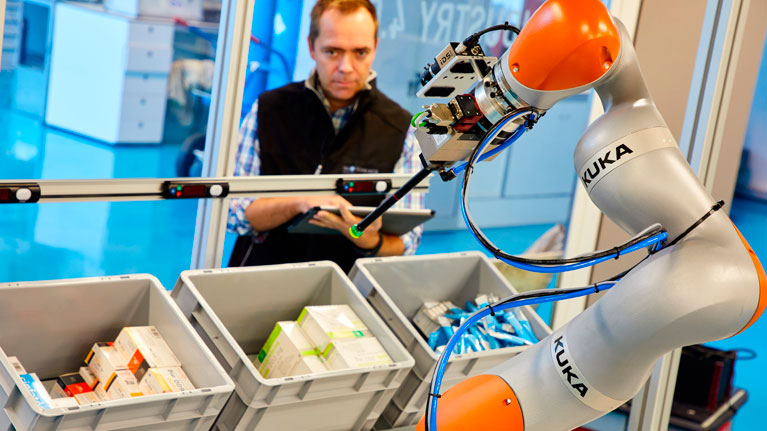

Bin-picking solutions combine artificial vision to identify parts to be removed and robotics for handling.

The handling of materials in production processes used to feed machines and process orders is a low added value task that can be automated.

Automating these activities, however, is usually a complex task due to a number of reasons: associated costs, ROI, product variability and how the material reaches the machine, among other factors.

Bin-picking has been addressed in the area of research and with the assistance 3D viewing technology, it nowadays seems plausible to offer industrial solutions.

Technologies for bin-picking

Bin-picking is a solution for an industrial demand related to removing parts from containers or bins, which features artificial vision to identify the parts to be removed and robotics for handling.

Artificial vision analyses a 3D image to identify and determine the position of very diverse objects such as metallic parts or other elements featuring different materials or geometries that are stored in containers.

Once an object has been identified and selected, the trajectory planning system governs robot movements and provides the orientation required to remove the object without colliding against the walls of a container or other nearby elements.

Robots that handle materials have been in use for decades in the industry and in the field of logistics. This technology, however, is inefficient in cases with a higher degree of complexity related to the presence of many different products, dimensions and packages.

Bin-picking solutions are attractive for processes requiring a repetitive and rapid extraction of elements from boxes or containers that are be subsequently processed and packaged. Such is the case of the food business with the machines used for production, order processing, warehouse palletizing, etc.

Further information

For further information, visit the webpage Automation and Industrial Robotics.