The first reactor ever to transform CO2 on Mars into space fuel

The Tekniker technology centre is leading the HISRU focused on developing a reactor that can exploit the potential offered by environmental conditions on the red planet to produce methane to be used as rocket fuel.

In the context of space exploration, In-situ Resource Utilization (ISRU) refers to activities and processes that benefit from resources available on other plants or moons that will allow future space missions to produce their own supplies in lengthy stays and, consequently, minimise the amount of materials to be transported from Earth so that astronauts can operate more independently and the cost of space trips can be reduced.

In 2022, and in order to use resources better and optimise the economic efficiency of future missions to Mars manned by European astronauts that are launched by the European Space Agency (ESA), the Tekniker technology centre, a member of the Basque Research and Technology Alliance (BRTA), has taken on a leadership role in the HISRU project whose ultimate goal is to develop, together with the University of Cantabria, the first system ever that will be able to recycle carbon dioxide found in in 95% of the red planet’s atmospheric composition.

In the course of this project, the technology centre will specifically develop an innovative, efficient and robust reactor that will use CO2 to produce methane and obtain fuel for space rockets.

Borja Pozo, a researcher and coordinator of the space sector at Tekniker, explains that “the system will use solar power and grey water produced by domestic chores performed by astronauts as a source to create the chemical reactions required to transform CO2 into methane. By doing so, it will become possible to boost the re-utilisation of already existing resources in space missions and astronauts will be able to produce their own fuel during their mission on Mars.

The technology centre and the University of Cantabria will perform a number of preliminary tests involving several materials and will launch an initial design for the prototype. Moreover, a testing campaign will be carried to verify the extent to which this unit could be used in space missions and also prove that the materials chosen, the configuration, the technologies and solutions adopted are feasible and can be applied when on Mars.

Design and validation

In order to meet the challenge posed by ESA, that is providing 100% of the funding required to deliver an enhanced photoelectrochemical (PEC) system that can reduce CO2 and be connected to grey water treatment facilities, researchers at the technology centre and the university will take into account the needs of future interplanetary missions to Mars and the planet’s solar and atmospheric conditions.

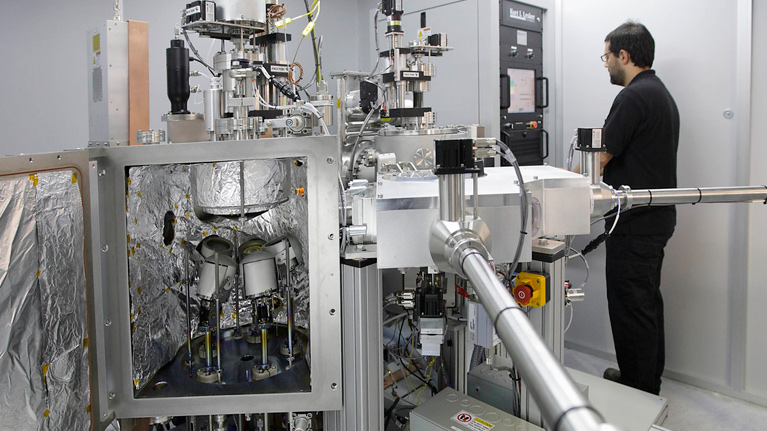

Consequently, research actions will focus on the materials required to develop this system and special attention will paid to operational features, efficiency, solidity, simplicity, scalability, ease of mechanical integration, minimisation of costs and the degree of compatibility with current and future space developments. In this regard, the magnetron sputtering technique, in which Tekniker is an expert, is associated with significant advantages with regard to how these materials can be processed.

Borja Pozo stresses that “this magnetron sputtering technology allows us to manufacture nanostructures of a precise morphology, size and composition to maximise the activity and efficiency of photoelectrochemical systems”.

The composition of grey waters will also be investigated and a compensation will be defined and implemented so it can operate adequately as an electrolyte for the cell.

In the case of waste waters, when organic contents (including pathogens) are oxidised in a photoelectrochemical cell it becomes possible to detoxify water and use it for other purposes. This process will help to reduce CO2 and produce fuel via direct conversion by using solar light as a power source.

Once stage one of the project concludes, work will focus on designing, developing, manufacturing and assembling the photoelectrochemical reactor under the supervision and approval of ESA and all operations will be verified and validated in a laboratory setting. The system will be tested under solar conditions similar to those prevalent on Mars, with controlled grey waters to produce methane by continuously reducing CO2 and directly in the gas phase to meet all the technical requirements established in the definition of the testing campaign.

Finally, an industrialisation road map will be defined to develop the photoelectrochemical cell commercially and system scalability parameters (service life, efficiency, size, etc.) will be established for future developments.

Addressing climate change

The highly promising outcomes of this project would not only have an impact on the space race, but also on the Earth and how we address climate change, as they could deliver key information to decarbonise our atmosphere properly.

Borja Pozo and Jonathan Cabo, a Doctor 13 Professor at the University of Cantabria, agree with this when they point out that “it would be possible to apply this technology, for instance, to solutions focused on reducing carbon dioxide in the industry or developing new similar products that can reutilise grey waters produced by companies or means of transport such as boats and motorhomes”.

The HISRU project (Photoelectrochemical system for CO2 reduction to produce fuels and sewage treatment), supported by the University of Cantabria, comes under an ESA campaign called “Towards a Sustainable Hydrogen Production Technology” and will be carried out between January 2022 and June 2023.

The aim of this ESA campaign is to generate new proposals to further technological expertise in the area of artificial synthesis in a transition that will eventually allow air to be decarbonised and produce hydrogen in a more sustainable manner.