Tribology

TEKNIKER studies the tribological design, the engineering of materials and surfaces, which allow, with the appropriate interface or lubrication, to work in real conditions (e.g. extremes and controlled environments) with minimum energy expenditure, noise and environmental impact during their life cycle.

The main objective is the understanding of the mechanisms of friction, mechanical wear, chemical wear (corrosion) and the wear-corrosion synergy at different scales (nano-macro), their simulation and modelling using laboratory tests and mathematical calculations. And, in this way, apply it in order to increase the quality of life and durability of the contact surfaces of actual components, studying their compatibility and type of interaction with the environment.

The correct functioning of almost any mechanical system depends on maintaining appropriate levels of friction and wear (mechanical or chemical) in the moving parts. The wear phenomena (e.g. abrasion, adhesion, sub-surface fatigue (pitting) wear-corrosion, fatigue- corrosion, erosion) are direct consequences of the failure to sufficiently consider the tribological design in mechanical components.

Therefore, TEKNIKER researches the tribology of:

- Advanced lubricants (e.g. biodegradable, ionic liquids)

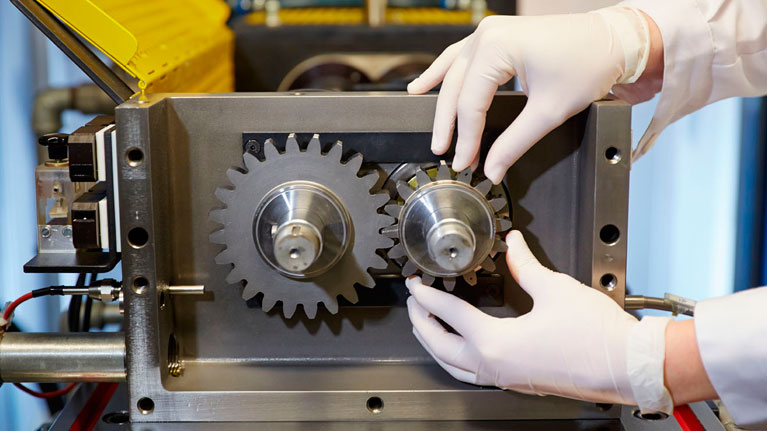

- Metallic materials and components (e.g. bearings, seals, gears, pistons, piston rings, engine sleeves)

- Tribology of polymeric materials (e.g. seals, elastomers, polymers, composites, floorings...)

- The biotribology

- Tribology of textiles and footwear requiring a multifunctional behaviour (e.g. abrasion resistance and antimicrobial performance)

To characterise the properties of friction, wear and wear-corrosion of materials and lubricants, it is possible to perform standard tests as well as to adapt existing equipment to perform configurations adjusted to specific problems or to develop new test benches according to customer needs. Such equipment is complemented by auxiliary equipment for analysing the wear of components (e.g. confocal microscopes or scanning electron microscopes) and a complete laboratory for analysis of lubricants.

Related contents

- Array ( [id] => 42 [idcategoria] => 2 [idsubcategoria] => [imagen] => IMG_Tribologia_767x431.jpg [caso_exito_1] => 53 [caso_exito_2] => 54 [caso_exito_3] => 55 [cliente_1] => [cliente_2] => [cliente_3] => [direcciones_email] => consultasweb@tekniker.es [titulo] => Tribology [video] => [texto_1] =>

- Advanced lubricants (e.g. biodegradable, ionic liquids)

- Metallic materials and components (e.g. bearings, seals, gears, pistons, piston rings, engine sleeves)

- Tribology of polymeric materials (e.g. seals, elastomers, polymers, composites, floorings...)

- The biotribology

- Tribology of textiles and footwear requiring a multifunctional behaviour (e.g. abrasion resistance and antimicrobial performance)

- Test bench for power re-circulating or Four Square gearbox

- Distance between centres: 91.5 mm

- Ranges of velocity: 100 to 3000 rpm (possibilities of 1:1 and 25:1 reduction)

- Transmission ratio: 1:1.5

- Maximum torque: 1000 Nm

- Lubricant bath by spraying

- Control and monitoring of the oil temperature

- Characterisation of lubricants for gearboxes. Standard tests for scuffing, pitting, micropitting, etc. (DIN 51354-1/2, ISO 14635-1, ASTM D 4998, FVA 54/I-IV, etc.)

- Characterisation of materials, surface treatment and gearbox geometry

- Analysis of surface damage (surface wear and fatigue), transmission error, power losses, vibrations, noise, root tension, variation of temperature of the oil.

- Reciprocal, circular motion

- Type of motion: sliding, rolling and sliding/rolling

- For dry and lubricated tests and tests with electrolytes

- Point, line and surface contact

- Normal load: 50 µN to 10,800 N

- Temperature: cryogenic to 800 °C

- Atmosphere: gases, vacuum, ultra high vacuum, corrosive media

- Wide variety of tribometers to determine the behaviour of materials, coatings and lubricants against friction, wear and wear-corrosion

- Standard and special tests as per customer requirements

- Simulation testing on actual components reproducing the wear mechanism present in its application

- Linear speed up to 6 m/s

- Rotational speed up to 2500 rpm

- High and low pressures

- Dry and lubricated

- Customised test chambers

- Monitoring of pressures and temperatures in chamber

- Characterisation of sealing systems:

- Various configurations

- Various geometries (O-rings, lip, composite, guide rings)

- Wide range of materials (TPU, NBR, FKM, PTFE, EPDM…)

- Testing of friction, wear and leaks

- Testing of joints:

- Axle and piston

- Hydraulics and Pneumatics (compressed air, N2, He, etc.)

- Rotating and reciprocating movement

- Design of customised test chambers

- Applications: automotive, pneumatic and hydraulic cylinders, hydraulic pumps, valves, etc.

- Normal load: 22-9000 N

- Speed: 5-10,800 rpm

- Temperature: ambient to 800 °C

- Testing of axially loaded tapered bearings

- Analysis of the surface deterioration of the bearings after a determined number of cycles

- Vibration analysis

- Control and monitoring of the evolution of the temperature during testing

- Comparison of the behaviour of different fats and oils

- Configurations of uni-directional (rotational) and bidirectional (oscillatory) movement

- Ball on disk and pin on disk contacts

- Temperature-controlled tests

- Option of working at different loads, amplitudes, frequencies and speeds

- Combined corrosion-wear tests in aqueous or conductive medium

- Characterisation of coatings and metallic materials

- Determination of friction, resistance to corrosion and wear, determination of the mechanical-corrosion synergy, loss of material due to purely mechanical effects and loss of material due to purely electrochemical effects

- Standardised testing and development of new tests according to the application

- Abrasive: alumina 50 µm

- Angle of incidence: 15, 30, 45, 60, 75 and 90º

- Speed of particles: 30 to 100 m/s

- Discharge rate: 1 to 5 g/min

- Temperature: ambient to 400°C

- Material erosion from an abrasive injected by a jet of pressurised air

- Determination of the erosion resistance of materials and coatings

- Tests under standard ASTM G76

- Ideal for evaluating materials and coatings working in desert environments

- Three parameters can be measured:

- Total mass loss

- Collected condensable materials

- Amount of vapour collected

- Ability to test four samples at a time

- Adjustment of test temperature

- Standards: ASTM E595-07 and ECSS-Q-70-02A

- Technique to evaluate the volatile content of materials and lubricants exposed under vacuum conditions:

- Evaluation of the volatile content of materials and lubricants.

- Volatility of oils and fats

- Volatility of textiles

- Volatility of polymers

- Volatility of coatings

- Gas pressure range: 5x10-9 to 103 mbar

- Amplitude of the reciprocal test: Maximum 20 mm

- Normal load: 10 mN to 20N

- Speed: 0.002 to 7 mm/s

- Temperature range: cryogenics up to 500 °C

- Minimum detectable desorption rate: 10-10 mbar/s

- Friction and wear testing of materials, coatings and lubricants in vacuum and ultra high vacuum

- Scratch tests in vacuum

- Analysis of the gases desorption and of the tribochemical reactions

- Analysis of the gases content in materials

- Testing in laboratory and in situ

- Tests under standards for the pendulum: UNE-ENV 12663, CEN/TS 16165

- Tests under standards for the GMG tribometer: DIN 51131, CEN/TS 16165

- In-house testing

- Friction and wear of flooring materials.

- Determining the degree of slipperiness of floors

- Tests on dry and wet floors or with any type of contaminant (oil, sand, water, cleaning products...)

- Drag torque measurements between a surface and seawater at different rotational speeds

- Rotational speeds: 0-1500 rpm

- Measuring torque less than 1Nm

- Measuring drag resistance as a function of temperature, speed, pH, oxygen content. Evaluation of the paint´s antifouling protection and its influence on reducing fuel consumption and preventing wear, abrasion and erosion

- Evaluation of antifouling coatings

- Influence of the variation in the roughness of the coating on the friction of the same with seawater at different speeds (laminar and turbulent regime)

- Testing for leaching of the paint for further evaluation of its toxicity

- Load: 250 to 1000 g

- Speed: 60 or 72 rpm

- Grinding wheels: CS-17, CS-10, CS-10F, H-18, H-22, H-38, H-10, S-35, CS-0, S-32, CS-35, S-39

- Determination of the abrasion resistance of materials and coatings

- Option to add abrasive particles (sand) during the test

- Multitude of standard tests: ASTM C 501, UNE EN 660, ISO 8251, UNE EN 14322, ASTM D 4060, JIS H 850

- Titanium autoclave for constant loads/LCF 25kN. 1 litre capacity, maximum test temperature of 300ºC and pressure of 16MPa.

- Electrochemical pack comprising a potentiostat, reference electrode Ag/AgCl and graphite counter electrode. Integrated software for controlling electrochemical parameters during the mechanical testing.

- Ceramic autoclave for constant load and stress up to 25kN. Maximum working temperature up to 800°C with simultaneous controlled input of up to three gases inside the autoclave

- Resistance to stress corrosion cracking of materials/coatings

- Simulation at constant load or under stress conditions

- Electrochemical and mechanical analysis of the materials set forth

- Simulation of the behaviour of materials in various corrosive environments at temperatures of up to 300°C and under pressure

- Simulation of the behaviour of materials in various corrosive gases, O2, SO2, NOx, etc. at temperatures of up to 800°C

- Fractographic analysis of materials/coatings

- Torque evaluation in cutting and forming operations

- Determination of the efficiency of lubricants

- Various configurations (threading, shaping, drilling, reaming tests)

- Characterisation of the torque and the efficiency of cutting and forming fluids

- Effects of roughness, surface treatments of sheeting to be formed

- Effects of the tool coating on the generated torque and the efficiency

- Evaluation of the angle of contact

- Calculation of surface energy

- Ability to perform tests at high temperature

- Evaluation of the hydrophobicity/hydrophilicity

- Evaluation of the angle of contact

- Evaluation of the surface energy

- Evaluation of the Leindenfrost effect

- Evaluation of the stress by rolling on Ball on Rod point contact

- Evaluation of the stress by rolling on Cylinder on Cylinder line contact

- Determination of durability of the material/coating up to pitting generation

- Automatic test limit by increasing vibrations

- Double test unit

- Variable speed up to 12,000rpm

- Determining the durability of steel in relation to stress by rolling (pitting) in point (ball bearing) or line (roller bearing) contact

- Effect of the coating on the durability by pitting

- Testing under conditions of rolling or sliding applying loads of µN, mN or

- Evaluation of the coating friction

- Ability to perform fretting tests

- Friction testing of coatings irrespective of the substrate

- Correlation between the friction with the micro-tribometer and the wear at macro scale

- Allows to differentiate areas with different coefficients of friction in the same material

- Behaviour of electronic components when faced with fretting

TEKNIKER studies the tribological design, the engineering of materials and surfaces, which allow, with the appropriate interface or lubrication, to work in real conditions (e.g. extremes and controlled environments) with minimum energy expenditure, noise and environmental impact during their life cycle.

The main objective is the understanding of the mechanisms of friction, mechanical wear, chemical wear (corrosion) and the wear-corrosion synergy at different scales (nano-macro), their simulation and modelling using laboratory tests and mathematical calculations. And, in this way, apply it in order to increase the quality of life and durability of the contact surfaces of actual components, studying their compatibility and type of interaction with the environment.

[fase_1] => [fase_2] => [fase_3] => [fase_4] => [texto_2] =>The correct functioning of almost any mechanical system depends on maintaining appropriate levels of friction and wear (mechanical or chemical) in the moving parts. The wear phenomena (e.g. abrasion, adhesion, sub-surface fatigue (pitting) wear-corrosion, fatigue- corrosion, erosion) are direct consequences of the failure to sufficiently consider the tribological design in mechanical components.

Therefore, TEKNIKER researches the tribology of:

To characterise the properties of friction, wear and wear-corrosion of materials and lubricants, it is possible to perform standard tests as well as to adapt existing equipment to perform configurations adjusted to specific problems or to develop new test benches according to customer needs. Such equipment is complemented by auxiliary equipment for analysing the wear of components (e.g. confocal microscopes or scanning electron microscopes) and a complete laboratory for analysis of lubricants.

[texto_tabla] => [enlace_flickr] => https://www.flickr.com/photos/teknikerik4/sets/72157650235978597/ [enlace_youtube] => https://www.youtube.com/playlist?list=PLdI9ptv1PWExlEqTh50XRXuSQjQwTCj07 [enlace_issuu] => [enlace_slideshare] => [seo_h1] => Tribology [seo_url] => tribology [seo_title] => Tribology - TEKNIKER [seo_desc] => We study the tribological design, which allow to work in real conditions with minimum energy expenditure, noise and environmental impact. [imagenes] => [enlaces] => Array ( [0] => Array ( [imagen] => [titulo] => Centro Superior de Investigaciones Científicas (CSIC) [texto_corto] => [enlace] => http://www.csic.es [alt] => Centro Superior de Investigaciones Científicas (CSIC) ) [1] => Array ( [imagen] => [titulo] => European Technology Platform for Advanced Engineering Materials and Technologies (EUMAT) [texto_corto] => [enlace] => http://www.eumat.eu [alt] => European Technology Platform for Advanced Engineering Materials and Technologies (EUMAT) ) [2] => Array ( [imagen] => [titulo] => Energy Materials Industrial Research Initiative (EMIRI) [texto_corto] => [enlace] => https://emiri.eu/ [alt] => Energy Materials Industrial Research Initiative (EMIRI) ) [3] => Array ( [imagen] => [titulo] => Austrian Excellence Center for Tribology (AC2T) [texto_corto] => [enlace] => http://www.ac2t.at/en/ac2t/ [alt] => Austrian Excellence Center for Tribology (AC2T) ) [4] => Array ( [imagen] => [titulo] => Competence Centers for Excellent Technologies (COMET) [texto_corto] => [enlace] => https://www.ffg.at/en/comet-competence-centers-excellent-technologies [alt] => Competence Centers for Excellent Technologies (COMET) ) [5] => Array ( [imagen] => [titulo] => TNO, Netherlands Organisation for Applied Scientific Research (Holanda) [texto_corto] => [enlace] => https://www.tno.nl/en [alt] => TNO, Netherlands Organisation for Applied Scientific Research (Holanda) ) [6] => Array ( [imagen] => [titulo] => VITO [texto_corto] => [enlace] => https://vito.be/en [alt] => VITO ) [7] => Array ( [imagen] => [titulo] => DTI, Danish Technological Institute (Dinamarca) [texto_corto] => [enlace] => http://www.dti.dk/ [alt] => DTI, Danish Technological Institute (Dinamarca) ) [8] => Array ( [imagen] => [titulo] => Universidad de Lovaina (Bélgica) [texto_corto] => [enlace] => https://www.kuleuven.be/english/ [alt] => Universidad de Lovaina (Bélgica) ) [9] => Array ( [imagen] => [titulo] => Polito, Politécnico de Turín (Italia) [texto_corto] => [enlace] => http://www.polito.it [alt] => Polito, Politécnico de Turín (Italia) ) [10] => Array ( [imagen] => [titulo] => Universidad de Miño (Portugal) [texto_corto] => [enlace] => http://www.uminho.pt/en/home_en [alt] => Universidad de Miño (Portugal) ) [11] => Array ( [imagen] => [titulo] => 2B FUNTEX (Europa) [texto_corto] => [enlace] => http://www.2bfuntex.eu/ [alt] => 2B FUNTEX (Europa) ) [12] => Array ( [imagen] => [titulo] => BIC, Bio-based Industries Consortium (Europa) [texto_corto] => [enlace] => http://biconsortium.eu/ [alt] => BIC, Bio-based Industries Consortium (Europa) ) [13] => Array ( [imagen] => [titulo] => Ducom Instuments (Holanda) [texto_corto] => [enlace] => http://ducom.com/ [alt] => Ducom Instuments (Holanda) ) [14] => Array ( [imagen] => [titulo] => Anton Paar (Suiza) [texto_corto] => [enlace] => http://www.anton-paar.com/ [alt] => Anton Paar (Suiza) ) [15] => Array ( [imagen] => [titulo] => Univ. Southampton [texto_corto] => [enlace] => http://www.southampton.ac.uk/ [alt] => Univ. Southampton ) [16] => Array ( [imagen] => [titulo] => Eureka E-Surf [texto_corto] => [enlace] => http://www.eurekanetwork.org/e_surf/about [alt] => Eureka E-Surf ) [17] => Array ( [imagen] => [titulo] => EMMC [texto_corto] => [enlace] => http://emmc.info/ [alt] => EMMC ) [18] => Array ( [imagen] => [titulo] => EDA [texto_corto] => [enlace] => http://www.eda.europa.eu/ [alt] => EDA ) [19] => Array ( [imagen] => [titulo] => EIFFO [texto_corto] => [enlace] => http://www.eiffo.de/de/ [alt] => EIFFO ) ) [publicaciones] => Array ( [0] => Array ( [titulo] => Prediction of Moulds Wear in High Pressure Die Casting and Plastic Injection Moulding [enlace] => prediction-of-moulds-wear-in-high-Pressure-die-casting-and-plastic-injection-moulding ) [1] => Array ( [titulo] => Comportamiento tribológico de polímeros en condiciones de deslizamiento [enlace] => Comportamiento-tribologico-de-polimeros-en-condiciones-de-deslizamiento ) [2] => Array ( [titulo] => Effect of mounting misalignments on the tribological behaviour of elastomeric seals: Analytical predictive models and experimental validation [enlace] => Effect-of-mounting-misalignments-on-the-tribological-behaviour-of-elastomeric-seals-analytical-predictive-models-and-experimental-validation ) [3] => Array ( [titulo] => Towards the standardization of nanoecotoxicity testing: Selection of environmentally relevant methods [enlace] => towards-the-standardization-of-nanoecotoxicity-testing-selection-of-environmentally-relevant-methods ) [4] => Array ( [titulo] => A new concept of bio-multifunctional nanotubular surfaces for dental implants: tribocorrosion resistant, antibacterial and osteogenic [enlace] => a-new-concept-of-bio-multifunctional-nanotubular-surfaces-for-dental-implants-tribocorrosion-resistant-antibacterial-and-osteogenic ) [5] => Array ( [titulo] => Tribocorrosion of high-strength low-alloy steels and coatings used in offshore applications [enlace] => tribocorrosion-of-high-strength-low-alloy-steels-and-coatings-used-in-offshore-applications ) [6] => Array ( [titulo] => Dispositivo de medida de fuerza [enlace] => en/inventions#PCT/ES2009/070635 (España, Prioridad 29/12/2009), US 8789430, USA IK4-TEKNIKER ) [7] => Array ( [titulo] => Soporte de muestra para ultra alto vacío [enlace] => en/inventions#PCT/ES2010/070273 (España, Prioridad 29/04/2010), US 13/643,581 IK4-TEKNIKER ) [8] => Array ( [titulo] => Mezclas sinérgicas de líquidos iónicos con otros líquidos iónicos con o sin aditivos sin cenizas basados en ditiofosfatos para aplicaciones de reducción de la fricción y el desgaste [enlace] => en/inventions#13/889,037 (USA, Prioridad 7.05.2003), IK4-TEKNIKER, en colaboración con la Univ. Texas, AC2T, Univ. Halle ) [9] => Array ( [titulo] => The effect of doping elements and oil additives on the tribological performance of boundary-lubricated DLC/DLC contacts [enlace] => the-effect-of-doping-elements-and-oil-additives-on-the-tribological-performance-of-boundary-lubricated-dlc/dlc-contacts ) [10] => Array ( [titulo] => New contributions to granite characterization by ultrasonic testing [enlace] => new-contributions-to-granite-characterization-by-ultrasonic-testing ) [11] => Array ( [titulo] => Influence of temperature on tribological behaviour of ionic liquids as lubricants and lubricant additives [enlace] => influence-of-temperature-on-tribological-behaviour-of-ionic-liquids-as-lubricants-and-lubricant-additives ) [12] => Array ( [titulo] => Evaluation of the optoelectronic properties and corrosion behavior of Al2O3-doped ZnO films prepared by dc pulsed magnetron sputtering [enlace] => evaluation-of-the-optoelectronic-properties-and-corrosion-behavior-of-al2o3-doped-zno-films-prepared-by-dc-pulsed-magnetron-sputtering ) [13] => Array ( [titulo] => Editorial: LUBMAT 2012-lubrication, maintenance and tribotechnology [enlace] => editorial-lubmat-2012-lubrication-maintenance-and-tribotechnology ) [14] => Array ( [titulo] => Comportamiento frente a la corrosión y el desgaste de nuevos recubrimientos superficiales desarrollados por medio de técnicas avanzadas. [enlace] => comportamiento-frente-a-la-corrosion-y-el-desgaste-de-nuevos-recubrimientos-superficiales-desarrollados-por-medio-de-tecnicas-avanzadas ) [15] => Array ( [titulo] => Aplicación de desoxibenzoínas a la síntesis de derivados heterocíclicos. Preparación de isoflavonoides, piridinas, pirimidinas y benzopiranoisoquinolinas [enlace] => aplicacion-de-desoxibenzoinas-a-la-sintesis-de-derivados-heterociclicos-preparacion-de-isoflavonoides-piridinas-pirimidinas-y-benzopiranoisoquinolinas ) ) [sectores] => Array ( [0] => Array ( [titulo] => Aeronautics and space [seo_url] => aeronautics-and-space [imagen] => aeronautica.svg ) [1] => Array ( [titulo] => Automotive [seo_url] => automotive [imagen] => automocion.svg ) [2] => Array ( [titulo] => Renewable energy [seo_url] => renewable-energy [imagen] => energias_renovables.svg ) [3] => Array ( [titulo] => The science industry [seo_url] => the-science-industry [imagen] => industria_ciencia.svg ) [4] => Array ( [titulo] => Infrastructures [seo_url] => infrastructures [imagen] => infraestructuras.svg ) [5] => Array ( [titulo] => Machine tools and manufacturing [seo_url] => machine-tools-and-manufacturing [imagen] => maquina_herramienta.svg ) ) [soluciones] => Array ( [0] => Array ( [titulo] => Automation and industrial robotics [seo_url] => automation-and-industrial-robotics [imagen] => ST_AutomatizacionRobotica_808x450px_icono.jpg ) [1] => Array ( [titulo] => Sensor devices [seo_url] => sensor-devices [imagen] => ST_DispositivosSensores_808x450px_icono.jpg ) [2] => Array ( [titulo] => Inspection and measuring [seo_url] => inspection-and-measuring [imagen] => ST_InspeccionMedida_808x450px_icono.jpg ) [3] => Array ( [titulo] => Industrial maintenance [seo_url] => industrial-maintenance [imagen] => ST_MantenimientoIndustrial_808x450px_icono.jpg ) [4] => Array ( [titulo] => Mechatronic systems [seo_url] => mechatronic-systems [imagen] => ST_SistemasMecatronicos_808x450px_icono1.jpg ) [5] => Array ( [titulo] => Multifunctional surfaces [seo_url] => multifunctional-surfaces [imagen] => ST_SuperficiesMultifuncionales_808x450px_icono.jpg ) ) [equipamiento] => Array ( [0] => Array ( [id] => 21 [titulo] => FZG gearbox test bench [imagen] => Banco_Ensayo_Engranajes_FZG.jpg [texto] =>EXPERTISE

CHARACTERISTICS OF THE EQUIPMENT

EXPERTISE

CHARACTERISTICS OF THE EQUIPMENT

EXPERTISE

CHARACTERISTICS OF THE EQUIPMENT

EXPERTISE

CHARACTERISTICS OF THE EQUIPMENT

EXPERTISE

CHARACTERISTICS OF THE EQUIPMENT

EXPERTISE

CHARACTERISTICS

EXPERTISE

CHARACTERISTICS OF THE EQUIPMENT

EXPERTISE

CHARACTERISTICS OF THE EQUIPMENT

EXPERTISE

CHARACTERISTICS OF THE EQUIPMENT

EXPERTISE

CHARACTERISTICS OF THE EQUIPMENT

EXPERTISE

CHARACTERISTICS OF THE EQUIPMENT

EXPERTISE

CHARACTERISTICS OF THE EQUIPMENT

EXPERTISE

CHARACTERISTICS OF THE EQUIPMENT

EXPERTISE

CHARACTERISTICS OF THE EQUIPMENT

EXPERTISE

CHARACTERISTICS OF THE EQUIPMENT

EXPERTISE

Industrial sectors

Singular equipment

- FZG gearbox test bench

FZG gearbox test bench

CHARACTERISTICS OF THE EQUIPMENT

CHARACTERISTICS OF THE EQUIPMENT- Test bench for power re-circulating or Four Square gearbox

- Distance between centres: 91.5 mm

- Ranges of velocity: 100 to 3000 rpm (possibilities of 1:1 and 25:1 reduction)

- Transmission ratio: 1:1.5

- Maximum torque: 1000 Nm

- Lubricant bath by spraying

- Control and monitoring of the oil temperature

EXPERTISE

- Characterisation of lubricants for gearboxes. Standard tests for scuffing, pitting, micropitting, etc. (DIN 51354-1/2, ISO 14635-1, ASTM D 4998, FVA 54/I-IV, etc.)

- Characterisation of materials, surface treatment and gearbox geometry

- Analysis of surface damage (surface wear and fatigue), transmission error, power losses, vibrations, noise, root tension, variation of temperature of the oil.

- Tribometers in a wide range of test conditions

Tribometers in a wide range of test conditions

CHARACTERISTICS OF THE EQUIPMENT

- Reciprocal, circular motion

- Type of motion: sliding, rolling and sliding/rolling

- For dry and lubricated tests and tests with electrolytes

- Point, line and surface contact

- Normal load: 50 µN to 10,800 N

- Temperature: cryogenic to 800 °C

- Atmosphere: gases, vacuum, ultra high vacuum, corrosive media

EXPERTISE

- Wide variety of tribometers to determine the behaviour of materials, coatings and lubricants against friction, wear and wear-corrosion

- Standard and special tests as per customer requirements

- Simulation testing on actual components reproducing the wear mechanism present in its application

- TESSA seals test bench

TESSA seals test bench

CHARACTERISTICS OF THE EQUIPMENT

- Linear speed up to 6 m/s

- Rotational speed up to 2500 rpm

- High and low pressures

- Dry and lubricated

- Customised test chambers

- Monitoring of pressures and temperatures in chamber

EXPERTISE

- Characterisation of sealing systems:

- Various configurations

- Various geometries (O-rings, lip, composite, guide rings)

- Wide range of materials (TPU, NBR, FKM, PTFE, EPDM…)

- Testing of friction, wear and leaks

- Testing of joints:

- Axle and piston

- Hydraulics and Pneumatics (compressed air, N2, He, etc.)

- Rotating and reciprocating movement

- Design of customised test chambers

- Applications: automotive, pneumatic and hydraulic cylinders, hydraulic pumps, valves, etc.

- Equipment for testing tapered bearings

Equipment for testing tapered bearings

CHARACTERISTICS OF THE EQUIPMENT

- Normal load: 22-9000 N

- Speed: 5-10,800 rpm

- Temperature: ambient to 800 °C

EXPERTISE

- Testing of axially loaded tapered bearings

- Analysis of the surface deterioration of the bearings after a determined number of cycles

- Vibration analysis

- Control and monitoring of the evolution of the temperature during testing

- Comparison of the behaviour of different fats and oils

- Tribocorrosion meters

Tribocorrosion meters

CHARACTERISTICS OF THE EQUIPMENT

- Configurations of uni-directional (rotational) and bidirectional (oscillatory) movement

- Ball on disk and pin on disk contacts

- Temperature-controlled tests

- Option of working at different loads, amplitudes, frequencies and speeds

EXPERTISE

- Combined corrosion-wear tests in aqueous or conductive medium

- Characterisation of coatings and metallic materials

- Determination of friction, resistance to corrosion and wear, determination of the mechanical-corrosion synergy, loss of material due to purely mechanical effects and loss of material due to purely electrochemical effects

- Standardised testing and development of new tests according to the application

- Airjet Erosion Tester

Airjet Erosion Tester

CHARACTERISTICS OF THE EQUIPMENT

- Abrasive: alumina 50 µm

- Angle of incidence: 15, 30, 45, 60, 75 and 90º

- Speed of particles: 30 to 100 m/s

- Discharge rate: 1 to 5 g/min

- Temperature: ambient to 400°C

EXPERTISE

- Material erosion from an abrasive injected by a jet of pressurised air

- Determination of the erosion resistance of materials and coatings

- Tests under standard ASTM G76

- Ideal for evaluating materials and coatings working in desert environments

- DEMETRA: volatility tests

DEMETRA: volatility tests

CHARACTERISTICS

- Three parameters can be measured:

- Total mass loss

- Collected condensable materials

- Amount of vapour collected

- Ability to test four samples at a time

- Adjustment of test temperature

- Standards: ASTM E595-07 and ECSS-Q-70-02A

EXPERTISE

- Technique to evaluate the volatile content of materials and lubricants exposed under vacuum conditions:

- Evaluation of the volatile content of materials and lubricants.

- Volatility of oils and fats

- Volatility of textiles

- Volatility of polymers

- Volatility of coatings

- CATRI: Ultra High and High Vacuum Tribometers

CATRI: Ultra High and High Vacuum Tribometers

CHARACTERISTICS OF THE EQUIPMENT

- Gas pressure range: 5x10-9 to 103 mbar

- Amplitude of the reciprocal test: Maximum 20 mm

- Normal load: 10 mN to 20N

- Speed: 0.002 to 7 mm/s

- Temperature range: cryogenics up to 500 °C

- Minimum detectable desorption rate: 10-10 mbar/s

EXPERTISE

- Friction and wear testing of materials, coatings and lubricants in vacuum and ultra high vacuum

- Scratch tests in vacuum

- Analysis of the gases desorption and of the tribochemical reactions

- Analysis of the gases content in materials

- GMG tribometer and pendulum

GMG tribometer and pendulum

CHARACTERISTICS OF THE EQUIPMENT

- Testing in laboratory and in situ

- Tests under standards for the pendulum: UNE-ENV 12663, CEN/TS 16165

- Tests under standards for the GMG tribometer: DIN 51131, CEN/TS 16165

EXPERTISE

- In-house testing

- Friction and wear of flooring materials.

- Determining the degree of slipperiness of floors

- Tests on dry and wet floors or with any type of contaminant (oil, sand, water, cleaning products...)

- Drag Friction Tester (ARGO)

Drag Friction Tester (ARGO)

CHARACTERISTICS OF THE EQUIPMENT

- Drag torque measurements between a surface and seawater at different rotational speeds

- Rotational speeds: 0-1500 rpm

- Measuring torque less than 1Nm

EXPERTISE

- Measuring drag resistance as a function of temperature, speed, pH, oxygen content. Evaluation of the paint´s antifouling protection and its influence on reducing fuel consumption and preventing wear, abrasion and erosion

- Evaluation of antifouling coatings

- Influence of the variation in the roughness of the coating on the friction of the same with seawater at different speeds (laminar and turbulent regime)

- Testing for leaching of the paint for further evaluation of its toxicity

- Abrasion (TABER)

Abrasion (TABER)

CHARACTERISTICS OF THE EQUIPMENT

- Load: 250 to 1000 g

- Speed: 60 or 72 rpm

- Grinding wheels: CS-17, CS-10, CS-10F, H-18, H-22, H-38, H-10, S-35, CS-0, S-32, CS-35, S-39

EXPERTISE

- Determination of the abrasion resistance of materials and coatings

- Option to add abrasive particles (sand) during the test

- Multitude of standard tests: ASTM C 501, UNE EN 660, ISO 8251, UNE EN 14322, ASTM D 4060, JIS H 850

- Stress Corrosion Cracking (CORMET)

Stress Corrosion Cracking (CORMET)

CHARACTERISTICS OF THE EQUIPMENT

- Titanium autoclave for constant loads/LCF 25kN. 1 litre capacity, maximum test temperature of 300ºC and pressure of 16MPa.

- Electrochemical pack comprising a potentiostat, reference electrode Ag/AgCl and graphite counter electrode. Integrated software for controlling electrochemical parameters during the mechanical testing.

- Ceramic autoclave for constant load and stress up to 25kN. Maximum working temperature up to 800°C with simultaneous controlled input of up to three gases inside the autoclave

EXPERTISE

- Resistance to stress corrosion cracking of materials/coatings

- Simulation at constant load or under stress conditions

- Electrochemical and mechanical analysis of the materials set forth

- Simulation of the behaviour of materials in various corrosive environments at temperatures of up to 300°C and under pressure

- Simulation of the behaviour of materials in various corrosive gases, O2, SO2, NOx, etc. at temperatures of up to 800°C

- Fractographic analysis of materials/coatings

- Tapping Torque Machine (FALEX)

Tapping Torque Machine (FALEX)

CHARACTERISTICS OF THE EQUIPMENT

- Torque evaluation in cutting and forming operations

- Determination of the efficiency of lubricants

- Various configurations (threading, shaping, drilling, reaming tests)

EXPERTISE

- Characterisation of the torque and the efficiency of cutting and forming fluids

- Effects of roughness, surface treatments of sheeting to be formed

- Effects of the tool coating on the generated torque and the efficiency

- Angle of contact

Angle of contact

CHARACTERISTICS OF THE EQUIPMENT

- Evaluation of the angle of contact

- Calculation of surface energy

- Ability to perform tests at high temperature

EXPERTISE

- Evaluation of the hydrophobicity/hydrophilicity

- Evaluation of the angle of contact

- Evaluation of the surface energy

- Evaluation of the Leindenfrost effect

- Ball on Rod and Cylinder on Cylinder Machine

Ball on Rod and Cylinder on Cylinder Machine

CHARACTERISTICS OF THE EQUIPMENT

- Evaluation of the stress by rolling on Ball on Rod point contact

- Evaluation of the stress by rolling on Cylinder on Cylinder line contact

- Determination of durability of the material/coating up to pitting generation

- Automatic test limit by increasing vibrations

- Double test unit

- Variable speed up to 12,000rpm

EXPERTISE

- Determining the durability of steel in relation to stress by rolling (pitting) in point (ball bearing) or line (roller bearing) contact

- Effect of the coating on the durability by pitting

- Nano-tribometer, CSEM

Nano-tribometer, CSEM

CHARACTERISTICS OF THE EQUIPMENT

- Testing under conditions of rolling or sliding applying loads of µN, mN or

- Evaluation of the coating friction

- Ability to perform fretting tests

EXPERTISE

- Friction testing of coatings irrespective of the substrate

- Correlation between the friction with the micro-tribometer and the wear at macro scale

- Allows to differentiate areas with different coefficients of friction in the same material

- Behaviour of electronic components when faced with fretting

Case studies

Partners network

- Centro Superior de Investigaciones Científicas (CSIC)

- European Technology Platform for Advanced Engineering Materials and Technologies (EUMAT)

- Energy Materials Industrial Research Initiative (EMIRI)

- Austrian Excellence Center for Tribology (AC2T)

- Competence Centers for Excellent Technologies (COMET)

Scientific excellence

- Prediction of Moulds Wear in High Pressure Die Casting and Plastic Injection Moulding

- Comportamiento tribológico de polímeros en condiciones de deslizamiento

- Effect of mounting misalignments on the tribological behaviour of elastomeric seals: Analytical predictive models and experimental validation

- Towards the standardization of nanoecotoxicity testing: Selection of environmentally relevant methods

- A new concept of bio-multifunctional nanotubular surfaces for dental implants: tribocorrosion resistant, antibacterial and osteogenic

- Tribocorrosion of high-strength low-alloy steels and coatings used in offshore applications

- Dispositivo de medida de fuerza

- Soporte de muestra para ultra alto vacío

- Mezclas sinérgicas de líquidos iónicos con otros líquidos iónicos con o sin aditivos sin cenizas basados en ditiofosfatos para aplicaciones de reducción de la fricción y el desgaste

- The effect of doping elements and oil additives on the tribological performance of boundary-lubricated DLC/DLC contacts

- New contributions to granite characterization by ultrasonic testing

- Influence of temperature on tribological behaviour of ionic liquids as lubricants and lubricant additives

- Evaluation of the optoelectronic properties and corrosion behavior of Al2O3-doped ZnO films prepared by dc pulsed magnetron sputtering

- Editorial: LUBMAT 2012-lubrication, maintenance and tribotechnology

- Comportamiento frente a la corrosión y el desgaste de nuevos recubrimientos superficiales desarrollados por medio de técnicas avanzadas.

- Aplicación de desoxibenzoínas a la síntesis de derivados heterocíclicos. Preparación de isoflavonoides, piridinas, pirimidinas y benzopiranoisoquinolinas